Saturday, December 23, 2006

Get Excited for 2007!

Thank you so much for signing up for Castilleja's Robotics Team: FIRST

Team 1700!

This will be our third season as a team, and we expect to rock! This email will outline the major dates for the 2007 season, what to expect and how to get involved. Please look it over, mark your calendars, and get psyched!

FIRST (For Inspiration and Recognition of Science and Technology), was founded in 1992 by Dean Kamen, "To create a world where science and technology are celebrated... where young people dream of becoming science and technology heroes". In 2006, its flagship program, the FIRST Robotics Competition, reached more than 28,000 high school students on

1,133 teams in 33 regional competitions. FIRST's multinational competition teams professionals and young people to solve an engineering design problem in an intense and competitive way. Its goal is to motivate young people to pursue education and career opportunities in science, technology, engineering, and math, while building self-confidence, knowledge, and life skills. Check out the website:

http://www.usfirst.org/community/frc/

Sat Jan 6, 2007 KICK OFF DAY! Meet at Castilleja, in the Choral Room, at 12 noon. Team leaders will be returning from San Jose State with the Challenge Announcement, Game Rules, and the Kit of Parts. Be ready to brainstorm, inventory all the cool gadgets and gizmos, and start working on the challenge. Plan on working with the team until 5pm. ALL PARENTS

are urged to stay at 12 noon for a special parent meeting to discuss team supervision, meals and logistics. Be there or be square - Lunch will be served!

As a reminder, the kick off day is the SATURDAY BEFORE school starts. Although we would love if everyone could come, we also realize that some of you might be away of vacation. Please let us know ASAP if you are unable to attend.

Sun Jan 7, 11 am to 5pm - continue brainstorming/ possibly prototype the robot.

Mon - Fri, Jan 8 - 14 (Global Week) We will meet daily after school 4 - 7 pm to work on the Challenge.

The team will work daily in the evenings after school, and weekends, to prototype and build the robot, develop the programming that controls it, create the team web site, and our team animation entry. Find the project that interests you most, work hard and HAVE FUN! We ask that Parents help provide supervision and meals.

Feb 20, 2007 Robot Shipping Deadline - Fed Ex will pick up our Robot by 5pm. Please note that the Ship Date is during Ski Week. This is usually the most intense time for build and programming, so we ask that everyone be here for it.

Feb 22, 2007 Website Design Deadline - our Website is up for Award consideration.

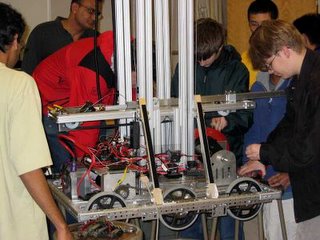

March 1 - 3, 2007 Pacific Northwest Regional FIRST competition in Portland, Oregon.

About a dozen team members will go. This is where we won the KPCB Entrepreneurship award in 2006.

March 15 - 17, 2007 Silicon Valley Regional FIRST competition at San Jose State Event Center.

All team members participate in this exciting tournament. This is where we won another KPCB Entrepreneurship award, and

the Engineering Inspiration Award in 2006.

April 12 -14, 2007 FIRST National Championships in Atlanta, Georgia.

About a dozen team members will go. This is where we won the Daimler Chrysler Team Spirit Award in 2006. Keep in mind that the Nationals are during the second weekend of spring Spring Break (meaning that we will leave the wednesday of break).

We'd love for the whole team to go to the out-of-town competitions, but unfortunately that is not financially or organizationally feasible. Team members will qualify to attend the out-of-state tournaments by hard work and dedication to meeting the goals of the team and through their "gracious professionalism."

Thank You and GET EXCITED!

PLEASE send me an e-mail saying that you have read this, and let me know if you are able to make it to kickoff, a simple yes or no in the subject line will suffice :)

THANK YOU!!!

Team Lead

-Chrissy Crone

(Cell: 650-339-2028)

Technical Lead

-Julia Lee

(Cell: 408-482-5196)

Non-Technical Lead

-Hannah Sachs

(Cell: 650-248-8687)

Thursday, December 14, 2006

More cool stuff

check out Jim's awesome shadow on the wall (in the welding fieldtrip album):

http://picasaweb.google.com/castilleja.robotics

Field Trip to Ideo + WELDING

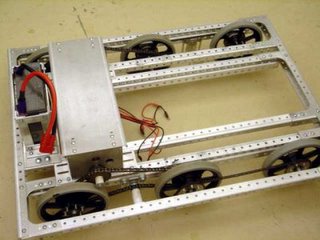

upon return to casti, we got to work drilling holes for wheels, playing with the electronics board, taking the old tread off the wheels and putting the spiffy new tread on. we're also working on putting together some new wheels, so yay!

have i mentioned how excited for the season i am?

...

i am SO excited for the season!!!

Friday, December 08, 2006

Field Trip to Alan Steel!

Happy Birthday, Erin.

Thursday, December 07, 2006

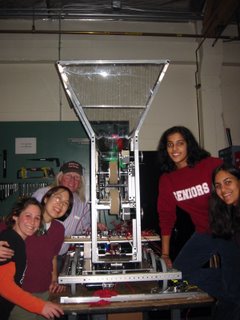

1st Build Meeting!

Tursday night we convened in the project room in the science wing (not the presentation rooms, fyi) from 5-7, as usual. Thanks to Nandini, Caroline, Sherri, and Melissa for showing up. We took the wheels we are going to re-use off Rosie (last year's robot) and assembled the other wheels to be used for this year's robot. We also drilled more holes in the proto-type chassis. Yep, lots of hands-on work : ) Hooray!

Sunday, July 16, 2006

CalGames (October 27-28)

Sorry I haven't had a chance to write back sooner!

It was really good to meet up at Google last Saturday with the CalGames folks from the Western Regional Robotics Forum (www.wrrf.org). Julia, just a warmning - the website sort of sucks. The information on it is outdated so I'll forward you information from Ceal Craig (one of the coordinators) after this email.

So, on the CalGames note, here are my thoughts:

I had lunch with Chrissy on Friday. She and I think it's going to take a lot of effort, and that we should make sure that we have a critical mass committed to doing this beforehand. This is not to be pessimistic or anything, but given that it is a volunteer-heavy event, if only like FIVE of us go, it's going to be painful. I *really* don't like it when someone commits me to doing / supporting something people don't pull through.

Kersten, I TOTALLY agree with you on the volunteering hours / community work thing. We can certainly recruit a lot of Casti students to come and the community hours thing is an incentive. Does the October 27-28 dates conflict with any school events?

On that note, I believe there is another option - if we DON'T want to enter as a team for the $600 entrance fee, there's nothing that says that we can't bring a gang of volunteers and new robotics rookies to HELP OUT! This would be low key, no prep in advance, and really great for exposing new students what a robotics competition is like, and of course, give them community service hours.

So here are my goals:

1. Bring at least 10 students to CalGames, of which at least 5 are new students. This is a great opportunity to expose newbies!

2. If we are serious about entering the competition, we should be serious about attempting to do well. I am not comfortable bringing new students to the competition and putting them at the wheel without at least attempting to leverage this opportunity to repair Rosie. I *do not* a new student's first experience with robotics to be a stressful one, where they watch us scramble before each match to make a new PVC chain tensioner. I just can't see myself being there watching that happen again.

If we don't have time to spend taking this competition seriously, we should considering going the less stressful route of putting our hearts into VOLUNTEERING FOR IT. I am not going to do anything half way.

3. Here are some realistic things that we can do to leverage this as a learning opportunity. Deadlines are GREAT for getting us to learn and getting us to do stuff during the off season.

* Build a new chassis. Kersten's learning to weld, and Julia is learning to put together weldment drawings in Solidworks. Chrissy has an Aluminum REM trip in the works. If we set aside some time and commit to this, I will do my part and convince Jimmy to give up a Saturday to work with you to design and weld an aluminum frame. This can be your test run before the US FIRST season. (Kersten, you'll discover that welding steel is a cinch, but aluminum is a whole another world that takes like years to learn)

* Improve the autonomous code and sensor / actuator systems. I'll work with Erin and Alecia to do this but this means we actually need a working robot that uh, drives straight when we ask it to.

My goal is help get people excited and bring people up to speed during the off season. CalGames can be the catalyst for that, but it doesn't need to be. Does that make sense? If CalGames takes all the wind out of me to coordinate and make happen, which means I have less time to teach people how to program, how to do electric stuff, gather materials and set up for the 2007, I would not be comfortable signing up.

Yeah.

Signing out,

Em

Monday, June 19, 2006

The Shop

What do you think of putting some shelving in the shop? Like, some actual robotics shelving, it might just be a shelf under the table in the back, but we could put, for example, the stuff currently in the corner of the project room down there and free up some space. I think it would be fine down there, we'd just have to make it clear that other people shouldn't touch it.

If there's no room for actual shelving, we might just clear a shelf on that rack by the back door and mark it "Robotics," put the long pieces up there, and store the smaller stuff under the table.

Kersten

Sunday, April 23, 2006

Maker Faire Blog Entry

Who was there? Kersten, George, Beth, Em, Eric, Debbie, Ryan, Ryan's friend, and possibly Chrissy and Heidi on Sunday?

This lightbulb / egg plotter is one of many cool things we saw!

Monday, April 17, 2006

Where are our bumpers?

They're the green ones. They're kindof important. We kindof need them in order to make new and better ones. Yeah. Get back to me on this.

ps- kudos to you who are reading the blog.

Sunday, April 16, 2006

general update: packing (oh boy!)

-we've put together three wheels from IFI robotics and they're a tiny bit lighter than our old wheels!!!

-chrissy and sophia will make bumpers

-i think we're meeting everyday this week (mon-fri) after school until about 4:30 or 4:45 (as usual).

-kersten essentially declared herself our resident packing expert, so chrissy and i have decided to let her do everything (ha ha!)

Friday, April 14, 2006

boxes

Also, I'm thinking we just wrap a lot of tape around the boxes to keep them from coming open (in addition to using the little holes for zip tying them closed), but does anyone have doubts about that? Because I can try to contact 114 and ask how they secured their stuff to Portland in the boxes, cuz that seemed to work.

We've got two boxes packed and (according to J Rock's unreliable scales) under the 50 (or is it 55?) lb weight limit, and looks like we can fit the rest of the stuff in the remaining three boxes fine. I hope nobody minds that we have some chunks of noodle in the bins, because we're too cheap to get actual bubble wrap. Since most of the stuff from the bins will be moved to the shelves, I figure storage for the noodles shouldn't be a problem in the pit.

If anyone is reading this, how about you give me a call and tell me if you can meet on Sunday (bear in mind that it's Easter for some of you). I think I might be able to, if I get my homework done.

Kudos to all the people who did cool stuff over break.

Kersten

Tuesday, March 28, 2006

Because 18 comments doesn't need one more

Thanks!

-the Dungeon Master

P.S. Yeah, I know I sent most people an email about this, but a U.R.L. told me to blog it as well.

Sunday, March 19, 2006

Atlanta

I was just thinking about stuff we need to get done (because you guys wouldn't let me start a list last night), and here's a preliminary list:

-pack tools and parts

-buy parts (like more zip ties. Unless we still have the billions that people gave to us)

-make a mobile pit, which we will actually need in Atlanta

-take more batteries

-repair our current bumpers

-make more bumpers (preferably better designed...)

-figure out how to attach bumpers (preferably some method that does not require zip ties, cool as they are)

-figure out how to tension our chain (also preferably some method that does not involve zip ties, because it means replacing them after every round)

-figure out what to do about our HUGE chassis rail bending/crooked wheel problem. We now only have two chassis rails that we can use from Thor, and as we now know, just replacing the ones on Rosie doesn't actually work. Unless maybe we try replacing the inside ones.....? We can discuss this.

-wash our gatorbotics shirts, because I'm sure they all smell.

-What else?

Yay, everybody, we're going to Nationals!!!!!!!!

Kersten

Friday, March 10, 2006

CG

Kersten's mother kindly reminded us that we can add 15lbs in bumpers to the base of our robot...!

Thursday, March 09, 2006

List from Chrissy/Kersten

-Make bumpers (Saturday, time TBD)

-Figure out if/how we're going to remodel our robot

-Tell people to bring the goggles they were given

-Advertise SVR to school

-Figure out what's going on each shelf

-Label shelves

-Velcro a power strip to shelf

-Take apart shelves

-Colaborate with the electronics team (what needs to be brought?)

-Put black shelves in car, to bring into pit only if necessary

To buy before SVR:

-green electrical tape

-black electrical tape

-bungy chords

-red locktite

-blue locktite

Tuesday, March 07, 2006

Tuesday

So if you take a look at the project room, well, it's an organized mess. We unpacked everything and had to go before we could relocate most of it into the boxes or tool chests. On the plus side, though, we have a mostly comprehensive first draft of a packing list of stuff to take to SVR (having inventoried what we unpacked from Portland). We also learned some more about shipping heavy things in plastic containers. What a 'learning experience' this has been. Yay.

See everyone tomorrow at the lunch meeting!

Kersten

Monday, March 06, 2006

not finished yet...

PLEASE COME HELP KERSTENS MOM UNPACK TODAY! SHE IS COMING AT 3:30 AND NEEDS HELP MOVING BUNCHES OF SUITCASES UP THE STAIRS AND UNPACKING THEM

THANK YOU!

Sunday, March 05, 2006

Portland regionals

Wednesday, February 22, 2006

Acidicly, we ROCK!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

kersten? is the digging machine party on? who do i talk to about that?

BUILD_ WE ARE NOT FINISHED, THIS WEEK WE NEED TO MAKE THE BUMPERS AND GET TOGETHER WHAT WE ARE GOING TO TAKE WITH US TO PORTLAND. AND NO, WE CANT TAKE EVERYTHING. WHEN WOULD PEOPLE LIKE TO MEET THIS WEEK? PERHAPS FRIDAY OR SATURDAY? OR IF WE END UP HAVING A PARTY, THAT COULD POSSIBLY INCLUED THE MAKING OF BUMPERS, (WHICH ARE NOT THAT COMPLICATED TO MAKE)

ON THAT SAME NOTE, DOES ANYONE HAVE 6 POOL NOODLES THAT WE COULD HAVE?

Sunday, February 19, 2006

Under the hood

Sophia, under the hood, re-soldering the connections to the potentiometer - worth its price in gold to see. Today has been a really amazing day. We spent the better part of the morning until early evening at IDEO and a certain office van dweller named Sven helped us transport Rosie back to Castilleja.

I'm overwhelmed and amazed by the generosity of so many people - Jim Feuhrer for stepping up this week pulling through a full seven days of midnight departures to build the hopper and the ramp, rebuild the turret plate, and mount multiple sensors, George Schnurle for coming by to give moral support and good humor even though his daughter is 3000 miles away, Doug Bourn for somehow managing to find time to come by even though he is up against an even tighter and tougher deadline at Tesla Motors, Eric Macintosh for some serious coding prowress, Bud Delisle for being there for the girls, Chris Countryman for animation advice and helping me in my braindead state to implement an RC switch debounce, George Aye for coming ALL the way from Chicago to offer his rendering expertise to Shirin, Beth Schnurle, Debbie Hara, and Heidi Crone for their undying wisdom, encouragement and support, and of course, David Berger for the famous quiche that keeps me coming back for more.

The Castilleja gymnasium is officially taken over by robotics for the next 48 hours. I think Rosie can go up against any basketball player. The kiddos brought a couch into the gym - they are all becoming serious couch potato roboticists.

This is a huge accomplishment for the team this year. We went from Thor, a robot with five motors and no sensors and no autonomous code last year to Rosie, a robot that has eight motors, three complicated sensors with interrupt code, and some sort of autonomous behavior to be yet determined. Still going with another 60 hours left. I'm really amazed that this team pulled it off. Even if Rosie is still in its infancy in terms of intelligence, she'll do some serious damage on the field . . . . ;)

Thursday, February 16, 2006

Extreme weight loss program worked! Jimmy and Bud and the gang took out all sorts of stuff - motor sprocket got taken down to half the weight, all the dead weight was removed, the transmissions were pulled out and the gears were pocketed, the 80-20 frame struts were removed (and still quite stable), the metal plate underneath the electronics box was cut down, the chain tensioners replaced by half links, chester turned into a leaner meaner metal plate . . . that's an entire 20 lbs gone!

9:30 pm Chrissy and I hooked both the launching motors and the gate motor up to a battery and successfully launched two balls in succession. Definitely a jumping up and down moment!!

One ounce at a time.

20 lbs = 320 ounces. One ounce at a time.

Not my idea, but I was working on the mill and it was really a kodak moment see both Jimmy and Bud work on the lathe at the same time for the same cause. The two of them are on a crusade now.

Wednesday, February 15, 2006

24 hour Hollywood Diet

i'm thinking south beach, or maybe slim-fast, 24 hour hollywood diet, perhaps the grapefruit or juicing diet, atkins, low-carb, low-fat, low-calorie, low sugar diet?

think light thoughts

think helium

think how we can lose 20 pounds

we'll make a fortune, "lose 20 pounds in under a week!"

for referance, 20 pounds is 2 batteries.

what could we cut holes in? what can we remove? what can we do without?

sleep on it, keep it in the back of your mind, and tomorrow we'll get something done.

Tuesday, February 14, 2006

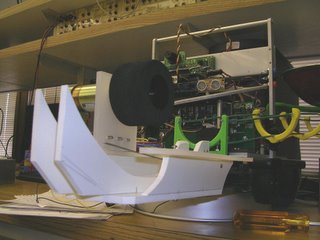

IDEO 11:30 pm Valentines Day

Jimmy just went home. Just wanted to post these two important photographs.

1. Jimmy, in all his kindness and generosity, couldn't put up with a direct drive motor, so after a quick mad race to find v-belt pulleys and a v-belt, we had something running by 11 pm tonight at IDEO. It is geared down by a factor of four, which means when you run the motor at maximum efficiency right now (approximately 6v), you get a really beautiful smooth motion.

2. We had to clean up the shop. It is becoming a bit of a problem here with the amount of room we are taking up. I also erased everything off the whiteboard so I've attached a photograph for programming above, just in case you need your pinout information. Eric McIntosh and Doug have been a great help getting the indexing system working with the interrupt.

It's been a tough tough week. Remember that although you can stay up late and have fun in your teens, us old and crotchety mentors don't last too many 11 pm days in a row.

I am going home now so I can sort of do my part on my real job.

- Emily

I love you all

To this day, I remember and regret losing a few great friendships because we didn't get along as a team on a project. It takes maturity and openmindedness to look beyond a tough and challenging experience to maintain a friendship through the trials and tribulations of team work.

In the end, even if we don't have a robot that is working, we have a friendship that we can cherish. Happy Valentines Day Gatorbotics!

A plea from programing

Thanks!

HAPPY VALENTINE'S DAY!

Monday, February 13, 2006

Moon Monday

Sunday, February 12, 2006

Sooooper Sunday

Bud, Jimmy, Kersten, Chrissy, Beth, Heidi and I got cranking this Sunday afternoon. Jimmy, especially, came in our hour of need and helped us think out of the box - literally. I had a lot of reservations about fixing the hopper to the chassis and have the turret rotate, given that we'd have a ramp cantilevered off the turret, and then Jimmy took a look at it and asked, can't we fix the hopper to the top of the turret as well? So given that we can expand to 60" by 60" once we start, having a 28" X 38" hopper that rotates is NO PROBLEM now.

As well, Jimmy WELDED a beautiful and light 3 lb. hopper frame for us. Now its all Chrissy's and Kersten's to add mesh and polycarb sheeting to.

We also did a bunch of brainstorming on the indexing / gating device. Instead of having the ramp come in from the side, the hopper allows the balls to come in from the top now, and we can float the gating device rather than have to cut slots in the ramp. More coming tomorrow. We're getting there.

One thing that was really useful for me today was to kind of mock everything up in terms of the launching sequence. With a bunch of things clamped to the launcher, and everyone helping ou and holding something, whether it was the gating device, or the ramp, we tried loading two balls down the hopper, and hooking up the gating device temporarily so it would turn and load balls one at a time. Man, that really helped solidify things for me.

Kudos to Chrissy and Kersten for the good work today prototyping the hopper with the mesh stuff. Lots of good prototyping and learning going on today that made it really fun!!!

TOMORROW. 5:30 pm. IDEO. BRING CHASSIS AS WELL.

Bud and I are both worried that with all the stuff on top of it, the launcher is going to bounce itself off the chassis and run away!!! See you later!!

The movie thing

So I think you guys told me what was going on in the movie and I couldn't remember if there was any Gracious Professionalism in it. I think including GP would be good if you can. Probably we don't want to buy gracious proffessionalism in the hardware store, cuz then it doesn't seem like we had it last year, but maybe if we buy a GP, like, refill or something? Or have a vat of it in the van that you can see from outside? I dunno. And if you already have it worked in somehow, that's awesome and you can ignore this.

Cheers!

Kersten

SUNDAY 1:20 at IDEO SHOP

demsions for where the ramp needs to go, along with angle and where it's going to be mounted. Bud made us sweet guides taht attach to the motor shaft so the thing stays square as a plus. aslo it isn't vibrating as much, so good. kersten had a good idea to mount t pieces of something as a ramp, so the ball would have to travel down the predetermined lane. we still need to decide where the window motor is going to be mounted. my mother and i got started watching the olympics and suddenly it's late, so we wont be prototying tonight...sorry :( but we got this KICK ASS netting stuff at home depot. it's for putting over plants and such so birds/dear don't eat them. it's really STRONG and WAY LIGHTER than the shower curtain...i'm also thinking it will be easier to mount (zip ties) and we got a roll 7' by 100' for $15, so i think that's a pretty good deal... :) it also looks WAY easier to mount. think seran wrap over a plate(i know it's spelled wrong and i dont care) we can take one sheet and lay it crosswise over another one, and then just cut a hole in the bottom. let's get to it!!!!!!!! we can finish this thing tomorrow...

Saturday, February 11, 2006

We created . . . a Mmmmonster!!

Named CHESTER!!

It also shoots like, um, a little to far now. Like across the field and 20 ft high, so we'll need to reduce / adjust the speed in software. I'm scared of this thing. I definitely don't want to be standing in front of it. We were hitting windows on on the second story in the IDEO alley way. We almost accidentally launched the ball onto the roof of the shop as well. Very scary.

Some issues we are dealing with:

- Structure seems to want to vibrate itself apart when the launcher is running (scary!!)

- No guides on the side, so sometimes the ball gets randomly sucked in sideways, resulting in shooting off to one corner. We definitely need to work on repeatability and accuracy a little bit more.

- Ramp? How are we going to secure the gate? So many things!!

Someone update me!!! What did Bud and you guys do after Kersten and I left for the rest of the afternoon?

Em

Backbot clarification

Quick Updates: Progress

OVERALL WEIGHT:

Not to overly worry about it yet, but we're definitely getting to the heavy side. We're sitting at 100 lbs - the chassis at 70 lbs and the turret frame structure at 33 lbs. This means we need to get EVERYTHING else in under 20 lb. Not impossible but definitely a little disconcerting.

TURRET:

Build team mounted the frame to the turret base with the casters on it. Looks pretty good. It's kind of cute actually, like a little deadly R2D2. How is programming doing with limiting the range - alas, I am worried about programming. Setting up the code and sensors to do this kind of thing doesn't just come together like in a day . . . and it needs to be fault proof or else our electronics board is getting it because that van door motor will stop at nothing!!

LAUNCHER:

Okay, we're at 33lbs. One way to get rid of the weight is to remove the entire yellow base all together. Seriously, because you have the square at the bottom holding your frame together, why not just bolt your casters to that and modify the motor shaft adapter to be a lot lighter?

We have all the parts needed for a 1:1 gear ratio now for the launcher. Both are 2.75" diameter pulleys. I also have a huge assortment of timing belts now just in case we run into some issues getting everything in the frame.

HOPPER:

With Chrissy and Kersten on it, we should be done in no time. Like finish TODAY. This is SATURDAY.

GATE AND RAMP:

Needs work. Sophia, Erin and I did a little b-storming and put together a little prototype. Now we need to figure out how to mount the motor to the ramp and how to stabilitze the structure of the ramp itself. Crazy stuff. Perhaps that 'flag post' we'll have at the back of the robot will be good to mount the ramp to.

OTHER STUFF: Is anyone thinking about this stuff?

- electronics cover

- PVC flag post (to display your alliance color)

- All your signage

- All your bumpers

Okay, signing out,

Em

Friday, February 10, 2006

Wednesday, February 08, 2006

Tuesday, February 07, 2006

Things are not as easy as they seem

We're coming along, but it's hard with 13 days left to discover that there are a lot of little things that need to be though through. For me, time is the biggest priority right now - and that is why I am advising you with that in mind, going for concepts that are easier to successfully implement in the time that we have left, rather than trying out fancy things. If this does not jive with you, please let me know. Your priorities are the most important and all I can do is give you my best advice and support based on my experiences, and you can take it or leave it.

What's left to do? A lot of stuff!

LAUNCHER:

Kersten and Julia did some mulling over getting the 45 degree angle on the launcher and came up with a great idea of having the wheels not be right on top of each other. Fantastic! Unfortunately, we came up a little short - literally today. The frame being smaller, Emily will need to order new shorter timing belt pulleys on Wednesday for Thursday delivery. Yes, it will be another two days before you can get the launcher finished because once again, lest I remind you that parts require time to get shipped.

TURRET:

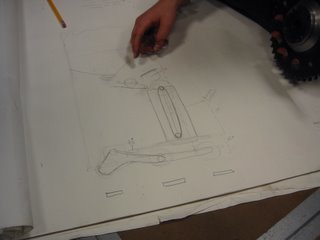

Aditi and Kersten put together a good plan for Bud to work on tomorrow, if he is free to do so. The plan was almost complete, and we talked about how a simple drawing with the hole patterns required to mount the frame as well as the casters would be useful since BUD is going to put the part on the CNC machine anyhow. I am going to stock the science project well from now on with graph paper. See my drawing below - you don't need CAD to covey to BUD or myself what you need done in the IDEO shop. (Kudos to Julia, who has already done this yesterday!)

GATE FOR BALLS:

Sophia, as much as I love your home made electromagnet, and as much as I appreciate you sharing those ideas with me, I have to admit your suggestion actually stressed me out a little bit. If this is your priority, please let us know and we'll focus on building an electromagnet, but I cannot ensure that we'll have something working for the gate by the end of this project. Again, I highly suggest choosing either the globe or denso motors, and just putting on a flag. Things take a LOT of time to calibrate. The build team hasn't really gotten to a point where they can understand how to structurally mount this motor so we're really waiting for them to reach that point as soon as possible.

BALL HOPPER / CATCHER:

Definitely needs some thinking. What is the plan here and how can we at IDEO help you out?

IN GENERAL:

With 13 days left, my realistic opinion is that we'll have a chassis that we can drive around and a turret that we can turn. The launcher, the ball hopper and the gate all still need to be integrated and I am not confident that this will happen in the time frame that we have.

At the core of this experience, it is my true pleasure to work with you, but I cannot help but to express my disappointment right now. You all had such high hopes at the beginning of the season and even with my hesitation, you managed to convince me that this was a path (shooting through the center goal. and getting the vision camera working) that we should take! This is no easy feat as I am not easily convinced. I am disappointed because of how things have come along, that we really aren't going to get to any of the autonomous stuff, nor the vision camera. That is fine, but I really wish you had told me not to spend the many hours I did already to understand the camera code, when we weren't going to really have a chance to use it at all. It's really frustrating being part of the programming team and not have anything to program or code when the hardware and the mechanical stuff isn't sorted out or even clearly conveyed to us. I will continue trying to be optimistic, but I am quickly running out of happy pills :(

A well planned engineering project and experience doesn't need to be like this. We don't need to stay up all night figuring things out. We don't need to work until the very last minute. Frankly, it would possibly be more useful to finish early and have the drivers get lots of practice with the robot. The truth is, as much as the rush of staying up all night in the very few last days, and as cool as we all think it might be, I don't think it's all that cool anymore. I wish we could work more efficiently and have clarity in what we do. Dang it, I want my 7 hours of sleep a night at my ripe old age of 24. I can't keep up with you anymore ;(

Monday, February 06, 2006

it's.....AAALLLLIIIIIVVVVVEEEEEEEE!

got kick-ass prototype from em at ideo today

tapped holes, took stuff apart, put stuff together

(can you tell that i'm tired? :)

tomorrow

aditi and i are getting to the project room at 3 to start working on either the base of the turret or the launcher, wherever our creative genius takes us. when you show up, we will assign you to either the launcher (which shouldnt be that hard to put together) or the turret.

GOALS

finish launcher by TOMORROW(this should be easy, guys. we have all the parts, we have all the specs, we just need to assemble)

finish turret by FRIDAY because programming needs to start coding. this is important if we want an autonomous code.

ok, that is it. tired.

nighty night!

Playing hookie at IDEO

Around 11 am on Friday morning, Bud, Jimmy and I received a large box from Mcmaster and sort of stopped working all together on our real work. Kersten, Julia and Kersten's mom came to join us in the shop around 5 pm and we played around with different wheels, different amounts of squish, and vertical vs. horizontal

Around 11 am on Friday morning, Bud, Jimmy and I received a large box from Mcmaster and sort of stopped working all together on our real work. Kersten, Julia and Kersten's mom came to join us in the shop around 5 pm and we played around with different wheels, different amounts of squish, and vertical vs. horizontalAnyhow, this is what came out of it. I'll post more on the process, and include a BOM (bill of materials) as well on how we put this together.

Check out the video: http://www.zippyvideos.com/4610912043602206/mvi_0653

Friday

OK, so I guess we kindof didn't meet on Friday, but Em invited the non-FOMF working people (aka me and julia) to ideo to play with this awesome little wheel prototype thing. I'm thinking we should try to get two wheels, because it works well, both vertically and horizontally. We can talk about it later once everyone has seen the prototype.Have fun FOMFing!And be sure to come to the SJ library, because that's the happenin' spot, you know.Kersten

posted by Kersten Schnurle at 8:06 AM

Thursday, February 02, 2006

BAD-ASS

so even if we cant do anything else, we can ram people. :)

but seriously, we got a lot done today.

CHAIN- Bud make us come kick-ass chain tensioners...when i first saw them i was kinda skeptical, but they work really well and get 500 points for visual appeal. yay! our back chain is tensioned!

for the front ones, we're going to go by last year's approch, bunny ears. since chain loosens up over time, if it does loosen up enoungh, we can always take the bunny off and put a bolt to tension it up more. good stuff.

BATTERY MOUNT- is almost finished. we just need to electrical tape-it so it doesn't conduct through the chassis (yikes) Props for good design by alecia! so now we can drive the robot around without strapping the battery to the side of the chassis with duct tape. haha.

LAUNCHER- built more of the platform and motor-securing device. it's almost finished so yay!

THINGS TO DO.

-mount bottom turret plate

-drilling holes to attach to chassis

- motor? directly to the plate (we already have a shaft hole and mounting screw holes. or we can put it elsewhere . sophia had a good idea. so direct drive the turret (van door hooked up to the plate) and in the middle put 2 gears, one on the shaft that is turning, and one on a potentiometer. they would have to be the same size gear...it sounds good to me...what do you thing emily?

-mount round turret plate.

-do we have the ball bearings? b/c we should attach them. we should also get another piece of aluminum to attach them to. get shaft and motor hooked up to the right place to fit

-ball feeder/storage

-posts need to go up. need to get materials for posts. EM- is there 80-20 that is 1/2" x 1/2" instead of 1 squared? that would be helpful.

-shower curtain, taught

-feeder to wheel (connection between storage and wheel. the prototype that Bud made us with the mousetrap maybe?

-MESH SIDES

-BUMPERS

-build and mount. specs are somewhere on the first site

-PVC pipe

-needs to start at 3ft and go up to 4ft, capped at the bottom

-NAME!!

ok so that's a lot to do. builders- no meeting this saturday (go to FOMF)but put your thinking caps on and get ready to rumble. these next two weeks are going to be killer.

and stress=dont do it. just say no. in the words of sophia through emily to me, we could build a robot that just moves in about 2 days, but what would we learn from that? or something like that.

Kilroy's Greatest Hits

Robot Name Link

http://cyborg.namedecoder.com/

Sara

Wednesday, February 01, 2006

A few turret questions

The biggest one that sort of concerns me (and please chime in Chris) is whether we should drive the turret directly or if we should drive it using a sprocket / chain setup. The reason why this decision isn't clear to me is because it AFFECTS PROGRAMMING. Chris, what is our plan to position sense, if any, if the the motor directly drives the turret? Or maybe we should let go of trying to do autonomous shooting and camera tracking all together?

took apart arm from last yaer, kersten designed an awesome motor mount thing so it doesn't move around.

jen and chirs and Jimmy took the aluminum plate over to ideo and drilled out a hole for the shaft. they are also drilling out holes for the side so we can attach it to the chassis.

in terms of the stainless steel plate, we cut one and a 1/2 of the sies, before the blade went out...boo-hiss.

so we still need a piece of aluminum for the turret, around 1/8 of an inch.

ok the computer just went dark so i cant really see anything, so ciao for now.

Perspective

By Saturday, FEBRUARY 5TH last year, with 17 days left, we had a completely functional arm. (How do I know, I took the photo to the left on that day, and it's marked with the date.

By Saturday, FEBRUARY 5TH last year, with 17 days left, we had a completely functional arm. (How do I know, I took the photo to the left on that day, and it's marked with the date.By THURSDAY, FEBRUARY 10TH (2005), we had a completely functional robot with 12 days left.

We will not be there this year. I am optimistic that we can possibly potential have something sort of all integrated by zero days left, but even with that I am not sure.

But that's one person's opinion,

Emily

Tuesday, January 31, 2006

Tuesday

Today the elctronics people did something with some oscilometers or whatever and found out that the speed controllers really weren't dead after all or something. Anyway, it was good news.

The build team (that's us!) put together a prototype spinner wheel of doom that Emily brought us, and put some bearings on Thor's tower and created a rough prototype of the actual launcher. We've got a long way to go, but let's try to stay just a bit optimistic- we will not die, for one. We can do this!

Next on the list is getting our wheel frame set up on the turret base and making sure that we secure everything and try to make the motor as happy as possible.

Ok, I'm going to go brush my teeth now. I hope you're enjoying your mojito, Em.

And remember- A little optimism goes a long way. We can do this a lot better and with a lot more spirit if we remember our cheer and that WE ARE DOING THIS FOR FUN. WE WILL NOT LET THIS KILL US BECAUSE THIS IS WHAT WE WANT TO BE DOING, right?

Goodnight, everyone, and get some sleep.

-Kersten

CAKE TODAY

started cutting the aluminum sheet

messed with electronics

put on third wheel (emily brought us fabulous newly cut hubs for the wheel, thank you!)

emily brought us a SPIFFY lauching wheel

doug brought us a cool new

today we...

put chain on third wheel on the left side

finish cutting aluminum sheet

use awesome new wheel

other stuff

realized this was supposed to be posted 2 hours ago. sorry...

Saturday, January 28, 2006

I am alive. Give me a name!

"This is your robot here writing to you. I started moving a little bit today. Please give me a name soon. Or perhaps you can name me 'Untitled' like one of those fancy paintings in museums if y'all are lazy butts" - Team 1700 Chassis

Rock on build team for getting lots done today!

Julia worked on getting all the components on the electronics board that Bud made and Emily and Beth screwed everything down.

Chrissy and Kersten went with Chris to Aluminum REM (which was closed by noon?) and went to a new fanagled place called Triangle Machinery or something like that. They brought back an 1/8" sheet of stainless steel and lots of bling. What fun!

Chrissy and Kersten also assembled much of the chassis, and tried earnestly to cut through the 1/8" thick sheet of stainless but wore out the jigsaw blade after 3 mm ;( Looking into options at Toolland and such.

Erin did a great job heat shrinking all our connections and doing some much needed labelling of parts. That's going to come in handy when we're debugging no doubt.

Christina, after a grueling morning with the SATs came by and patiently finished the turret i.e. filed open the holes for the limit switches to sit in. We have code to make the turret run, but will need to test it out. Once we get the turret running like we want it to, we'll bring in the camera code.

Doug came by and was put to work immediately on helping to debug the robot. We downloaded some code and discovered that the left transmission wasn't getting any input. We ruled out the code, and the power supplies, and are now focused on figuring out what is wrong with the drivers (speed controllers, Victor 488). Yikes. Much more to do here.

Emily is going to make two 'hubs' tomorrow and bring them to Kersten on Monday to test out so that we can try to avoid spending lots of money on new hubs. Boy are they expensive at IFI.

Bud is working on making a simple drill guide so that we can cut holes center on the 80-20, 0.5" from the edge.

Let's finish up the chassis soon (by Monday night?) so that the programming team can work to optimize some of the basic driving stuff.

Turret and launching mechanism need a lot of help as of today, from mounting the motor to building the structural elements. The faster we design and build everything, the more time we will have to actually make the code work. Debugging electronics code takes a long time!!

Cool. We're at 24 days left. Not many!

Em

name the robot competition

"saturday, saturday...saturday, saturday"

Kersten, Chris (countryman) and I went on a scavanger hunt for a piece of metal. it lead us the aluminum REM, which, after 1/2 hour of trying to open the side entrance door, ringing non-existant doorbells, waving money around, and talking into security cameras, we decided was closed. to confirm this, we went to the ajacent tool supply store where they told us that it was never open on weekends. boo-hiss. but they did give us KICK ASS directions to a place called Triangle Machinery, which is like Allen Steel, only not as big and a ::little:: more orginized. there we got some Bling Bling (no joke) and a sweet piece of 1/8" thick by 44"x28" for only $40. YESSS!

unfortunatly, when we tried to cut it to size, it took out the blade (as in now it's smooth)yipes. we found a place in san carlos that carries the right kind of blade, $20. ToolLand. but we're debating whether it is worth it or should we just go and get a big piece of aluminum because it is easier to machine. thoughts?

juila did more electronics. yay!

half our robot runs! yay! mounted electronics board! woo-hoo! now we're just waiting for 4 more hubs and we're good to go.

when i say half our robot runs, i'm saying that it is "running circles" around our compitition. in fact, it is running circles around everything, the field, the floor, people. (did i mention that the left side isn't moving?) but it's all good, because that will be fixed soon. yay for coders. and hooking things up right. let's be nice to the speed controlers b/c we just discovered that they're :quite: expensive.

In Other News...

I have officially been here for every light turn off except for 2am and 4am

we might be able to change that in the upcomming weeks... :) (evil laugh inserted here)

[Edit by Sophia: I've seen the 2am shut-off!]

and putting in my two cents, i like rosie the riveter for our robot name...

Friday, January 27, 2006

I, Wanna Rock and Roll All Night...

ok. here is my prediction. Every day in the upcoming week, the new robot (name yet to be fashioned) will look consiterably different

today we...

CHAINED THE FIRST TWO WHEELS!!! yay!

emily brought over a beautiful piece of electronics mastery that bud made, and julia started hooking up all the wires from the master circut breaker to the speed controlers. kersten is now the master chain breaker. i, on the other hand, had some *difficulty* with the chain. :)

also built a mini-turret for programming (it's not quite finished)to prgram camera with. mieter saw works wonderfully with aluminum.. :) (heh heh heh)

went to IDEO to use the arbor press to press bearings into wheels!

we still need 2 hubs for wheels.

tomorrow-

focus our efforts on hub-capping the wheels, which means that we will have one side that will run like a dream, and one that will will run like 2/3 of a dream. so that also means chain

more electronics. attaching wires to speed controlers takes longer than you think it does. maybe by the end we can mount the electronics on.

perhaps we could also design a battery mount and make it?

turret design, exact-ifyed

order a sporcket (we seem to have one missing...why they gave us an odd number i don't know)

order hubs (2)

make calls about steel/aluminum rods to hold up the shower curtain

make calls to alumimum places to get quotes on mounting plate for turret.

ok, over and out. comment something if i forgot it.

heavy metal (rock on)

3185 De La Cruz Blvd #2,

Santa Clara, CA 95054

(408) 748-0666

Like their name implies, Aluminum Rem Center is your place to get just about any size, shape, and type of aluminum you want. They charge by the pound (~$3.50/lb for Al). They're happy to cut to size as well but charge a little more (~$4.25/lb

Alan Steel

Highway 101 & Whipple (east)

Redwood City, CA

(650) 369-2526

Hours: M-F 8am-4:30pm, Sat closed, Sun closed.

Comments: Alan Steel, AKA Alan Steels, has a really great selection of base metals and stuff (salvage) made from base metals. This includes sheet, tubing, extrusions, rod, angle, and pallet material in aluminum, brass, steel, stainless steel and some plastics. You can also find giant gears, motors, fans, and all sorts of other random stuff. They charge to cut. This is a really great place to wander around just to get your creative juices flowing. They give deals to the fairer sex and on stuff they don't understand. Otherwise it's pretty pricey.

Thursday, January 26, 2006

"and then your mother was like..."

more demolishing of thor

(he's getting botox and liposuction)

more wheels on the chassis, the bearings will be in tomorrow so yay! then we'll have the full 6 wheels and we can put the chain on...woo-hoo!

we also lock-tighted screws, and moved the transmissions over a bit, realized they needed washers, unscrewed, washered them, screwed them back, realized we needed to lock tight, unscrewed, locktighted, screwed back in. we screwed those transmissions at least 6 times. damn.

yay for Doug! who showed us a bit about the electronics. we stipped some wires, connected them to the circut breaker and the main breaker. woo-hoo! and we connected them RIGHT this year! :)

aluminum/ steel sheets at mcmaster for the bottom underneath the turret:

7255K35: anodized alluminum, 3/8", 24"x24" at a whopping $255. is this normal? did i click on something special? agghh!

89155K28 - 3/8" 18"x18" aluminum for turret...only $122 (!)

88895K56 -think shet of aluminum if we do a steel one underneath...only 35$, but thickness is 1/8" 24"x24"

9019K517 steel - 3/16" thick, 18"x12" a damn **** load of money at $146.5

9720K37 - steel 1/8" thick, 24"x20" $269

still need to buy ball casters (unless emily, you've already ordered them?))(5674K51)

for holding up the shower curtain:

6535K31 - Perforated square steel, like swiss cheese, only less smelly 23.72/6'or something else

maybe we should go dumpster diving at ideo and see if we can fish up a large piece of metal. i think that is our best bet.

thanks to heidi for bringing food and cleaning the white board that Doug brought that is now mounted on the wall. yay!

ok. yeah.

c'ya tomorrow. it should be fun. wheels and transmission and chains OH MY!

Taking advantage of Bud's Free Time

Yet another pitch to learn Solidworks or some CAD program during the off season . . . next year, I'm definitely leaving this kind of thing for you to do!!

1. Electronics component layout. I am making an executive decision to use last year's circuit breaker / distribution panel instead of this year's setup (which involves hooking three boards together, taking up more room and more time and more complexity). You ask, is this allowed? Please read Update #2 on the US FIRST website. I have a suggested layout for the components. You need AT LEAST SEVEN speed controllers this year - 4 CIM chassis motors, 1 turret motor, 1 launcher motor, 1 gate motor at least. So the layout has room for eight speed controllers (remember we only had five last year) and it gets a little squishy, so planning is important. Also, the board allows for room to actually manage the wires and cables WITHOUT having them drape over the fans. By god . . . geezus. Yuck. I'm going to get Bud to cut the base out tomorrow, and we're going to BOLT all the components to the board and WIRE them all up so it's ready to. NOOOOO velcro this year on the electronics board . . . please please please.

2. Camera Test Platform. In order to get Christina, Shirin, Erin and Sophia something to do while the build team continues to resolve the turret issue, we're going to build a mini-turret so that we can mount the camera to it and start programming it to respond like we want it to when it goes on the main turret. Notice the mini turret also has two limit switches on it to detect the boundaries of a 90 degree field of view. We need this hardware to support our software development . . . badly. Hopefully bud will be able to churn this out tomorrow as well.

Wednesday, January 25, 2006

things to do tomorrow...

-finsh wheels. this means go to ace and get screws that are long enough and the right size. this also means finsh everything to do with the driving wheels. for example, CHAIN. do we still have a chain cutter? ACE again?

-work on mounting turret, if we dont have the materials for that, we can work on...

-electornics mount. i'm thinking poly carb. i really like the velcro from last year, but with poly carb we have the screw-in option and the velcro option. maybe a thick piece with nicely mounted electronics?

-box for camera...again, would polycarb work for this? sounds good to me, but what do i know? it would have to have some sort of anti-glare/anti-reflection material on the inside. yup.

STUFF we need to GET tomorrow...

(This is basically EM's list)

2'x 2' x 1/8" STEEL PLATE for underneath the turret (to mount it on)

5 ball casters to support the turret and make sure it yaws nicely (5674K51)

2' x 2' x 1/4" aluminum sheet

OR

2' x 2' x 1/2" MDF for on top of steel for the actual turret.

long metal hollow poles. about 45" tall. for holding shower curtains full of balls up. mcmaster or allen steel?

6535K31 - Perforated square steel, like swiss cheese, only less smelly 23.72/6'

6582K19 - square steel, 42.96/6'

6566K526 - rectangle - 43.23/6'

how thick does it need to be? em? j-rock? anyone else?

i'm leaning towards the cheesey one, b/c i just looked back at the rectangle and it meets aerospace and military specifications. i don't think it needs to be that heavy duty

none of them say how heavy the material is at mcmaster. ok, yeah

You guys rock

Goodbye, Thor... ::tear::

today we...

Pressed bearings into wheels with the help of emily and jimmy at ideo, and also found that we are 4 bearings short! (2 wheels are missing bearings) so emily the magnificent has ordered them.

CHASSIS!!!! CHASSIS!!!! CHASSIS!!!!!! (you KNOW)

once we got the bearings in with the arbor press, we came back to casti and got working on the chassis (haha...casti...chassis?! get it? it rhymes! yay!)(click)

we have mounted the transmissions and mounted two of the wheels on the chassis...which was harder than it sounds because we couldn't find the screws, didn't have enough couplers, and didn't have enough sprockets, so we stipped Thor of screws, cuplers, and sprockets (basically we took everything but the wheels and the grime)so Thor is now looking very disshevled but he knows that he is being put to good use. think of it this way, he's living on through our new robot...which we still need a name for.

yay for julia's mom, debbie, who came to chaperone us so j-rock doesn't have to live at castilleja. she also brought chinese food...yummm...thank you beaucoup!

also yay for doug who stopped by a little before 8 to help us out with questions and stuff

and TRIPLE YAY for ROBOTICS and our hot new chassis...

Tuesday, January 24, 2006

Tuesday Build (the diagram on the floor)

If you've read Chrissy's post, you'll know what I'm talking about. Just in case you don't want to get your butt over to the science project room.

If you've read Chrissy's post, you'll know what I'm talking about. Just in case you don't want to get your butt over to the science project room.[Click on the image to the left to enlarge it. After that, you might have to hover your cursor over the image for another 'enlarge' button to show up.]

A few things that we've been thinking about and stuff to do:

1. Wednesday (that's tomorrow), January 25, with 27 days left. IDEO shop 5:00 pm sharp. Bring skyway wheels and the 3/8" bore bearings that need to be press-fit into the wheels with the arbor press. Once you have the wheels with the bearings pressed in, you can start assembling the chassis. Leave out the middle wheels until Thursday - I have two more wheel sprockets coming in for you from IFI robotics. You can definitely start laying out the approximate amount of chain needed.

2. Thinking turret, yes! So Chris made a good suggestion that we could probably mount the motor to drive the turret directly. I think this is a good idea, but see my qualms below (mostly about gearing things down and being able to sense the angular change with our GTS). Less parts and thus less things to break. We'll need to plan accordingly i.e. probably build an adapter plate to mount the shaft to the turret. For now, I suggest we procure the following:

* 2'X2' 1/8" thick steel plate for the base (nice and heavy, and a hard surface). We'll bolt the motor to the plate from the underside.

* 5 ball casters (get one extra) from Mcmaster to support the turret and take the weight of the turret off the shaft off the motor (the motor should only be driving axial loads). The part number is 5674K51. Thanks to everyone who helped to figure what this widget was called!

* 2'X2' of some material for the turret. I say we can do 1/4" thick aluminum sheet or perhaps even easier, 1/2" MDF (particle board material, like the stuff that Bud used for his coolio prototype).

We might want to get some FLAT steel sprockets from Mcmaster, just in case we don't want to drive the turret directly. We can drill out holes to make them even lighter. I think mounting flat sprockets is much easier. Steel because Sophia reminded me that we need a ferromagnetic material if we're going to try to implement gear tooth sensors. As well, we might need to gear down the van door motor to run it slower!! Type in 'Steel hubless plain bore flat sprocket' at mcmaster to see what I mean.

3. Finally, blah blah. Actually, more important than that. Chris asked for some specs on the van door motor and it is biased. From last year's 'FIRST Guidelines' booklet, I find the following on the Van Door motor:

CLOCKWISE: Stall torque 34 Nm @ 44 Amps; No Load Speed 75 RPM

COUNTER CLOCKWISE: Stall torque 30 Nm @ 44 Amps; No Load Speed 75 RPM

Not a big deal, but what I read is that right now, you get a little more than 1 full rotation PER SECOND! That's 360 degrees in less than a second. We want to scan a field of view of 45 degrees for a total of 90 degrees - that would happen in 1/4 s! Eeek! Okay, that's at no load, but still!

Chris or Doug, I suspect if we gear down the Van Door motor 2:1, we'll hit the middle of the speed-torque curve, get max power, while slowing down the panning of the turret to something reasonable?

Okay, see you tomorrow at 5 pm at the IDEO shop!

- Emily

tuesday -design

-taped batteries

-design specs

-go into the project room and look down on the floor notepad for drawing and design.

turret, mounted underneath (no chain required)

for support, roller balls (kind of like ball bearings)on poly carb, on top of either steel or aluminum.

yes! today was really good!'

thanks to chris, sara,kris, and emily for comming!

hoo-rah!

more later as i have an essay to finish...haha

Get ready to rumble some more!!

Looks like you guys made some great headway yesterday (and dude, I totally wrote this post before I saw Chrissy's Schtuff)! I hope a Mcmaster order is going in today.

Are the following items on your list?

- Timing belt pulleys (yup)

- Timing belt (yup)

- Wheel or drive roller (duh)

- Shaft to support the output pulley

- Bearings to support the output shaft (remember you need them on both sides of the wheel)

- Shaft collars of the right bore diameter to affix the pulley to the output shaft

- Shaft collars of the right bore diameter to affix the motor pulley to the motor shaft

- Long 6" (10-24?) bolts for the mini-bike motor (there's one short one long right now . . .) to affix mini-bike motor to frame

- Any other items for your setup?

Alecia can be of great help to you now. Please consult her for:

- Shaft diameter of the mini-bike motor (she can pull up the file and tell you the radius and thus diameter)

- Check bolt size and thread pitch for the mini-bike motors

Finally, please start assembling the chassis soon!! Programming needs some time to tune their code to the dynamics of a six wheel chassis! With all the parts in hand except for 2 wheel sprockets (as we learned from Team 115 on their setup), assembling the chassis shouldn't take more than 1-2 sessions! Programming would love to be able to NOT be driving around Thor's big behind and start coding for this year's robot chassis instead!!

We're officially at 28 days gals!!

Doing well, with our collective understanding of the need for contingency plans ;)

Em

Monday, January 23, 2006

GET READY TO RUMBLE...

ORDERED THE AIR DUCT STUFF TO FEED THE BALL INTO THE LAUNCHER WITH

ORDERED THE SPINNING WHEEL FOR LAUNCHING THE BALL

ORDERED THE BELT IN ORDER TO SPIN THE WHEEL IN ORDER TO LAUNCH THE BALL

ORDERED THE PULLEY IN ORDER TO MOVE THE BELT IN ORDER TO SPIN THE WHEEL IN ORDER TO LAUNCH THE BALL!

(p.s. we decided on a belt instead of a chain because it's safer. i.e. if a chain is a little bit off, it will slip and come all the way off and flying into something at a large velocity. Ouch. if a belt is a little bit off, it's just a little bit off. b/c the wheel is moving so fast, we decided this would be a good thing)

(p.p.s. we also decided on ONE vertical wheel. launching from the TOP)

i will say that again.

WE HAVE DECIDED ON ONE VERTICAL WHEEL THAT LAUNCHES BALLS FROM THE TOP.

we have also decided that the center of the wheel is about 3 feet off the GROUND, 2 feet off the TURRET. this is non-negotiable. we have already ordered the belt for this lenght.

tomorrow we might take a trip to a hardware store. we will also finish up DESIGN SPECS. (i.e. finish materials list, sizes of materials, where to get them, etc.)

wednesday we'll build and finish design specs (if in case some odd thing comes up and we haven't finished them already (which we totally should)

thursday we'll send some of you to IDEO to press bearings into the wheels. the stuff we ordered today will probably be in by then so we'll be able to do more exciting build stuff.

welcome my friends...hope you have some time to spare... because we have just entered upon the building phase.

YEEESSSSSSSSSSSSSSSSS!!!!!!!!!!!!!!!!!

(heads up, first weekend in feb. there is no robotics. we will all be FOMFing, you should too...)(ps. SF library KICKS BUTT!)

Sunday, January 22, 2006

Through the hoop with 12 m/s, 30 degrees, 21 feet away

AND CLICK ON IMAGES BELOW TO ENLARGE AND READ THEM.

Math and physics is cool. Make me happy by at least attempting to be interested in figuring this out theoretically?

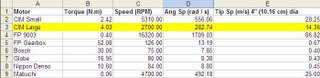

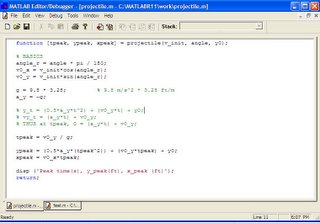

If you back out what Team 358 did, here is what you get:

CIM mini-bike motors give you an angular speed of 2700 RPM which equates to a tip speed of 14 m/s (As a comparison, your prototype with the transmission gave you an angular speed of 423 RPM which equates to a tip speed of 2 m/s - that's why it didn't go anywhere). Since the maximum speed allowed for balls leaving the field is 12 m/s, even with losses, this motor has a high enough torque in the range of output speeds that we need to be appropriate (please see excel spreadsheet below – as derived from Sophia’s motorspecs.xls).

Then you crank it through the projectile motion equations and you learn that, well, at 12 m/s, you can shoot the ball from 2.5 feet off the ground at a 30 degree angle, from 21 feet away (that’s pretty much 6 feet away from the center line (remember the field is 54’ by 26’), you will get it through the hoop, smack center. That’s if you have a clear line of sight.

Let me repeat: YOU WILL GET THE BALL THROUGH THE HOOP WITH THESE PARAMETERS

v_output = 12 m/s = 39 feet / s

height of muzzle = 2.5 feet

angle of muzzle = 30 degrees

horizontal distance from goal = 21 feet

See equations below:

Yes, this is no joke. Again, it's very clear that it is a solid solution that the veteran teams have already proven out. Let’s put our efforts into building a solid, accurate, robust shooter. There will be lots of accurate shooters this year. Let’s figure this one out.

- Emily

Saturday, January 21, 2006

the paparazzi is coming to get you

oh and, btw, alecia, those pics on angelfire look good. thanks for taking all of those and putting them up. maybe we could get more of programming and animation?

http://www.angelfire.com/planet/robotworld/casti_robotics/

and for the rest of you - watch your back. alecia is armed and dangerous with a camera.

*muah*

(+j-rock)(and ed)

we PROTOTYPED today!

yay!

We (mostly Kersten and Juila) built an awesome prototype of the two wheels horizontally from the transmission motors and the 2 wheels that Kersten, Aditi and I got this morning (7" diameter, about 1.5"thick.)it kicked butt.

also yay for Diti and Jen who got screws! woo-hoo

from the prototype we concluded

-the wheels will have to be much closer together than where we put them, the ball is really squishy and the more of it touching the wheel, the better

-we will not be using the transmission motors for the spinning wheels. They are too slow. I'm pretty sure we will use the CIM mini-bike motors. Bud and his infinite genius helped us get the funky top off the top of that thing, but we're still not quite sure what to do with the screw that is sticking up. I want to cut it off, because if we want to put anything on top of it, i.e. a gear, we will need the space . I'm not really sure what you'd use it for. But I could be completely in the dark. Emily? What do you think about this?

PRIORITY

vertical or horizontal?

-Since em mentioned the very good point that other robots could just sit and block us, I'm kind of thinking a vertical wheel because we could have it up higher and it would only be one, where as the 2 horizontal wheels i have trouble picturing higher up on the robot. hmmm...

ok. that's all except that I am having trouble finding a place that sells solid rubber wheels that are about 5 inches wide. boo-hiss.

last but not least,

a shout out to j-rock, who is always here (by here i mean at school) and lives far away. yay for him!

i like cake. i hope you guys do too... :)

Shooting from low, what happens if you're blocked.

It's like Chrissy or me trying to throw a basket ball over a 7' tall Yao Ming.

Do we want to give ourselves the best chance of having a clear shot? If so, it makes a difference to be taller!

Okay, now for bedtime.

Em

Kooky looking for now, but not for long . . .

Food for Thought: Dimensions

- Structural Frame: FIRST 2005 Kitbot (see the .IGES files?)

- Kit of Parts: AutoDesk Site login: (public)

The pain in the ass part was having to install Autodesk Inventor just to convert all the inventor .ipt parts to .iges so that I could import them to Solidworks.

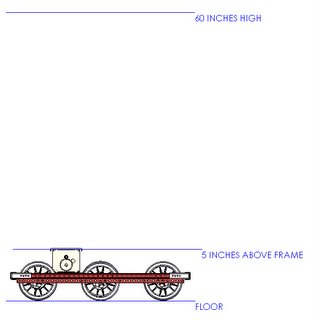

Here's a reminder of scale. Dude, yes, 60 inches in height is a LOT more than we think it is. Do we want to take advantage of it? Ain't Solidworks COOOOL?

Friday, January 20, 2006

"Rubber Ducky, You're The One..."

advatages of vertical wheel or horizontal wheels. will prototype tomorrow.

for the mesh NETTING on top- suggestion - use a clear plastic shower curtain, or one with rubber duckies or something cool and shower-curtain-like, so it's clear and strong. that way things won't get caught in it. yay.

we also discussed stuff, like what our angle of freedom on the turret should be, we're thinking around 120. yeah.

we're pretty sure that the angle of the shot WILL NOT MOVE. that means that it will YAW ( <----> )(side to side) but not PITCH (^ v )(up and down)

TOMORROW = PROTOTYPING

come prepared

we will:

-prototype vertical and horizontal wheel design with crap pnumatics from ace.

-test which motor we want to spin the shooter wheels

-press the bearings into the wheels (IDEO)

-put wheels on chassis.

ok my brain is dead, if i remember anything else, i'll post it.

that's a lot to do, and we can spilt up and do different things. get ready!!!

Thursday, January 19, 2006

"I'd like a side of fries and a fully functional robot, please..."

large goal = finished! (huge and in the gym, go check it out! it looks great)(also thanks to Eric (sara's bf the swedish carpenter)for helping us put it together!)

small goal = (mostly) finished!

Robot- jen, sophia, and I checked out the pitching machine over by the softball field today, and it actually looked pretty good. But instead of using a pneumatic tire (which we don't want because it would have to be the EXACT same pressure each time we shoot the ball for our shot to be consistent. Any variation in pressure means a variation in where the ball ends up. Not good)we were thinking maybe a solid rubber tire. (p.s. this is all if the wheel for shooting is vertical)Another thing to keep in mind is that on the pitching machine, the width of the wheel was about the diameter of the softball, so we'd want OUR wheel to be about 7 inches in width.

Does anybody know where to get a large-ish wheel that has a width of 7 in? or 6 in? 5 would be streching it. or in this case contracting. (click) Emily? the robot store doesn't have very many wheel options for us as far as i can tell, and Mcmaster is huge, where do we start looking for something like that?

We're going to PORTLAND because...

it will give us practice with the robot. more compition means we get better! Also, since the portland regional is before SVC, we'll be able to fine-tune our skills so we can use SVC to show off. :) we also have confidence that our PR team will get us some money. soon.

because my mother is a lead parent rep, (she meets with JLo and Blair once a month)she will be arguing on our behalf for money. just for the update, her argument is "why are we sending people to china and india if we can't even support our own science and technology programs? especially robotics!" good question mom.

Random thoughts (actually not too random but whatever)

hoo-rah for Mr. Berger and his amazing cooking skills.

wow upside down is mom

Doug's shelves make me happy every time i look at them

build team rocks

sleep lots this weekend, because soon you will not be gettting very much.

More Inspiration: Foam Peanut Dispenser

Benchmarking Ball Shooting and Pitching

Dear build team - perhaps the reason why I am bringing the vertical positioning on the table is because I've seen it done before, in baseball pitching machines, and in various mechatronics and robotics projects at the college level around the country. I guess I feel more comfortable for your success knowing that we're scaling up a proven concept, rather than going with our gut.

Here's the evidence that I've found from various sources:

1. The electrical engineering department at Stanford had a tournament one year that involved many launchers of this sort. For a photograph of the real robot, check out THIS PAGE.

2. Undergraduate students at the University of Illinois Urbana Champagne (an excellent engineering school) also solved a similar problem the same way. For more information about their task, check out THIS PAGE.

3. And finally, last but not least, here's a reminder of what a baseball pitcher looks like.

Help me prove out that your concepts also have high potential for success!

Yes, there are many nights I can't sleep because of you . . .

Em

Brand New Shelf!

Wednesday, January 18, 2006

wheel suggestion

http://www.robotcombat.com/marketplace_wheels.html

YAK wheels-large

$20 each

or the

NPC DRIVE wheels with delrin hubs

8"

$23.50

DON'T PANIC

HI

we've decided to use the wheels we were given as opposed to buying new ones. Maybe we can beef up the traction in the ones we've got. kersten suggested buying rubber. Sounds good to me. If anyone knows how expensive rubber sheets can get post a comment.

Doug brought us KICK BUTT new shelves. Doug rocks.

another lovely dinner from the Kasturia family...and fabulous cake...yummm...

on to real robot stuff.

we're mounting the turret about 5 in above the base of the chassis, so it doesn't hit the wheels.

CIM AP801-005 motor for spinning ball launcher wheels

radius: .08m = 22m/s

radius: .09m =25m/s

the .09 radius is better. We're going to use it.

18cm ball 18cm

[_______](------)[_______]

the only thing is we need a way to secure the motors ON AN ANGLE and make sure that THEY DO NOT MOVE. THIS MEANS SECURING THEM SECURELY. if we can't do that, (b/c there are appearently funky gyro forces at work) emily suggests vertical-izing the wheels. I am skeptical, but what do you all think?

ok. if i forgot anything, let me know.

How'd they do that? Driving Six Wheels . . .

By choosing to do six wheels, I had some serious concerns about being able to align all the wheels in the same plane. That's really important. So now we have one potential answer that's pretty good.

Often times, we open our eyes a little wider beyond what we think we know and can guess, and all our answers come flooding in.

Team 115 is here: http://www.mvrt.com/index.php?z=clear

It'd be awesome if they could help mentor us a little bit.