Tuesday, January 31, 2006

Tuesday

Today the elctronics people did something with some oscilometers or whatever and found out that the speed controllers really weren't dead after all or something. Anyway, it was good news.

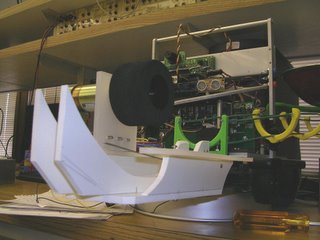

The build team (that's us!) put together a prototype spinner wheel of doom that Emily brought us, and put some bearings on Thor's tower and created a rough prototype of the actual launcher. We've got a long way to go, but let's try to stay just a bit optimistic- we will not die, for one. We can do this!

Next on the list is getting our wheel frame set up on the turret base and making sure that we secure everything and try to make the motor as happy as possible.

Ok, I'm going to go brush my teeth now. I hope you're enjoying your mojito, Em.

And remember- A little optimism goes a long way. We can do this a lot better and with a lot more spirit if we remember our cheer and that WE ARE DOING THIS FOR FUN. WE WILL NOT LET THIS KILL US BECAUSE THIS IS WHAT WE WANT TO BE DOING, right?

Goodnight, everyone, and get some sleep.

-Kersten

CAKE TODAY

started cutting the aluminum sheet

messed with electronics

put on third wheel (emily brought us fabulous newly cut hubs for the wheel, thank you!)

emily brought us a SPIFFY lauching wheel

doug brought us a cool new

today we...

put chain on third wheel on the left side

finish cutting aluminum sheet

use awesome new wheel

other stuff

realized this was supposed to be posted 2 hours ago. sorry...

Saturday, January 28, 2006

I am alive. Give me a name!

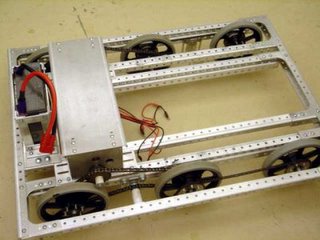

"This is your robot here writing to you. I started moving a little bit today. Please give me a name soon. Or perhaps you can name me 'Untitled' like one of those fancy paintings in museums if y'all are lazy butts" - Team 1700 Chassis

Rock on build team for getting lots done today!

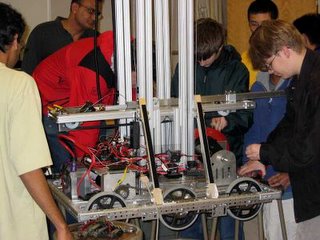

Julia worked on getting all the components on the electronics board that Bud made and Emily and Beth screwed everything down.

Chrissy and Kersten went with Chris to Aluminum REM (which was closed by noon?) and went to a new fanagled place called Triangle Machinery or something like that. They brought back an 1/8" sheet of stainless steel and lots of bling. What fun!

Chrissy and Kersten also assembled much of the chassis, and tried earnestly to cut through the 1/8" thick sheet of stainless but wore out the jigsaw blade after 3 mm ;( Looking into options at Toolland and such.

Erin did a great job heat shrinking all our connections and doing some much needed labelling of parts. That's going to come in handy when we're debugging no doubt.

Christina, after a grueling morning with the SATs came by and patiently finished the turret i.e. filed open the holes for the limit switches to sit in. We have code to make the turret run, but will need to test it out. Once we get the turret running like we want it to, we'll bring in the camera code.

Doug came by and was put to work immediately on helping to debug the robot. We downloaded some code and discovered that the left transmission wasn't getting any input. We ruled out the code, and the power supplies, and are now focused on figuring out what is wrong with the drivers (speed controllers, Victor 488). Yikes. Much more to do here.

Emily is going to make two 'hubs' tomorrow and bring them to Kersten on Monday to test out so that we can try to avoid spending lots of money on new hubs. Boy are they expensive at IFI.

Bud is working on making a simple drill guide so that we can cut holes center on the 80-20, 0.5" from the edge.

Let's finish up the chassis soon (by Monday night?) so that the programming team can work to optimize some of the basic driving stuff.

Turret and launching mechanism need a lot of help as of today, from mounting the motor to building the structural elements. The faster we design and build everything, the more time we will have to actually make the code work. Debugging electronics code takes a long time!!

Cool. We're at 24 days left. Not many!

Em

name the robot competition

"saturday, saturday...saturday, saturday"

Kersten, Chris (countryman) and I went on a scavanger hunt for a piece of metal. it lead us the aluminum REM, which, after 1/2 hour of trying to open the side entrance door, ringing non-existant doorbells, waving money around, and talking into security cameras, we decided was closed. to confirm this, we went to the ajacent tool supply store where they told us that it was never open on weekends. boo-hiss. but they did give us KICK ASS directions to a place called Triangle Machinery, which is like Allen Steel, only not as big and a ::little:: more orginized. there we got some Bling Bling (no joke) and a sweet piece of 1/8" thick by 44"x28" for only $40. YESSS!

unfortunatly, when we tried to cut it to size, it took out the blade (as in now it's smooth)yipes. we found a place in san carlos that carries the right kind of blade, $20. ToolLand. but we're debating whether it is worth it or should we just go and get a big piece of aluminum because it is easier to machine. thoughts?

juila did more electronics. yay!

half our robot runs! yay! mounted electronics board! woo-hoo! now we're just waiting for 4 more hubs and we're good to go.

when i say half our robot runs, i'm saying that it is "running circles" around our compitition. in fact, it is running circles around everything, the field, the floor, people. (did i mention that the left side isn't moving?) but it's all good, because that will be fixed soon. yay for coders. and hooking things up right. let's be nice to the speed controlers b/c we just discovered that they're :quite: expensive.

In Other News...

I have officially been here for every light turn off except for 2am and 4am

we might be able to change that in the upcomming weeks... :) (evil laugh inserted here)

[Edit by Sophia: I've seen the 2am shut-off!]

and putting in my two cents, i like rosie the riveter for our robot name...

Friday, January 27, 2006

I, Wanna Rock and Roll All Night...

ok. here is my prediction. Every day in the upcoming week, the new robot (name yet to be fashioned) will look consiterably different

today we...

CHAINED THE FIRST TWO WHEELS!!! yay!

emily brought over a beautiful piece of electronics mastery that bud made, and julia started hooking up all the wires from the master circut breaker to the speed controlers. kersten is now the master chain breaker. i, on the other hand, had some *difficulty* with the chain. :)

also built a mini-turret for programming (it's not quite finished)to prgram camera with. mieter saw works wonderfully with aluminum.. :) (heh heh heh)

went to IDEO to use the arbor press to press bearings into wheels!

we still need 2 hubs for wheels.

tomorrow-

focus our efforts on hub-capping the wheels, which means that we will have one side that will run like a dream, and one that will will run like 2/3 of a dream. so that also means chain

more electronics. attaching wires to speed controlers takes longer than you think it does. maybe by the end we can mount the electronics on.

perhaps we could also design a battery mount and make it?

turret design, exact-ifyed

order a sporcket (we seem to have one missing...why they gave us an odd number i don't know)

order hubs (2)

make calls about steel/aluminum rods to hold up the shower curtain

make calls to alumimum places to get quotes on mounting plate for turret.

ok, over and out. comment something if i forgot it.

heavy metal (rock on)

3185 De La Cruz Blvd #2,

Santa Clara, CA 95054

(408) 748-0666

Like their name implies, Aluminum Rem Center is your place to get just about any size, shape, and type of aluminum you want. They charge by the pound (~$3.50/lb for Al). They're happy to cut to size as well but charge a little more (~$4.25/lb

Alan Steel

Highway 101 & Whipple (east)

Redwood City, CA

(650) 369-2526

Hours: M-F 8am-4:30pm, Sat closed, Sun closed.

Comments: Alan Steel, AKA Alan Steels, has a really great selection of base metals and stuff (salvage) made from base metals. This includes sheet, tubing, extrusions, rod, angle, and pallet material in aluminum, brass, steel, stainless steel and some plastics. You can also find giant gears, motors, fans, and all sorts of other random stuff. They charge to cut. This is a really great place to wander around just to get your creative juices flowing. They give deals to the fairer sex and on stuff they don't understand. Otherwise it's pretty pricey.

Thursday, January 26, 2006

"and then your mother was like..."

more demolishing of thor

(he's getting botox and liposuction)

more wheels on the chassis, the bearings will be in tomorrow so yay! then we'll have the full 6 wheels and we can put the chain on...woo-hoo!

we also lock-tighted screws, and moved the transmissions over a bit, realized they needed washers, unscrewed, washered them, screwed them back, realized we needed to lock tight, unscrewed, locktighted, screwed back in. we screwed those transmissions at least 6 times. damn.

yay for Doug! who showed us a bit about the electronics. we stipped some wires, connected them to the circut breaker and the main breaker. woo-hoo! and we connected them RIGHT this year! :)

aluminum/ steel sheets at mcmaster for the bottom underneath the turret:

7255K35: anodized alluminum, 3/8", 24"x24" at a whopping $255. is this normal? did i click on something special? agghh!

89155K28 - 3/8" 18"x18" aluminum for turret...only $122 (!)

88895K56 -think shet of aluminum if we do a steel one underneath...only 35$, but thickness is 1/8" 24"x24"

9019K517 steel - 3/16" thick, 18"x12" a damn **** load of money at $146.5

9720K37 - steel 1/8" thick, 24"x20" $269

still need to buy ball casters (unless emily, you've already ordered them?))(5674K51)

for holding up the shower curtain:

6535K31 - Perforated square steel, like swiss cheese, only less smelly 23.72/6'or something else

maybe we should go dumpster diving at ideo and see if we can fish up a large piece of metal. i think that is our best bet.

thanks to heidi for bringing food and cleaning the white board that Doug brought that is now mounted on the wall. yay!

ok. yeah.

c'ya tomorrow. it should be fun. wheels and transmission and chains OH MY!

Taking advantage of Bud's Free Time

Yet another pitch to learn Solidworks or some CAD program during the off season . . . next year, I'm definitely leaving this kind of thing for you to do!!

1. Electronics component layout. I am making an executive decision to use last year's circuit breaker / distribution panel instead of this year's setup (which involves hooking three boards together, taking up more room and more time and more complexity). You ask, is this allowed? Please read Update #2 on the US FIRST website. I have a suggested layout for the components. You need AT LEAST SEVEN speed controllers this year - 4 CIM chassis motors, 1 turret motor, 1 launcher motor, 1 gate motor at least. So the layout has room for eight speed controllers (remember we only had five last year) and it gets a little squishy, so planning is important. Also, the board allows for room to actually manage the wires and cables WITHOUT having them drape over the fans. By god . . . geezus. Yuck. I'm going to get Bud to cut the base out tomorrow, and we're going to BOLT all the components to the board and WIRE them all up so it's ready to. NOOOOO velcro this year on the electronics board . . . please please please.

2. Camera Test Platform. In order to get Christina, Shirin, Erin and Sophia something to do while the build team continues to resolve the turret issue, we're going to build a mini-turret so that we can mount the camera to it and start programming it to respond like we want it to when it goes on the main turret. Notice the mini turret also has two limit switches on it to detect the boundaries of a 90 degree field of view. We need this hardware to support our software development . . . badly. Hopefully bud will be able to churn this out tomorrow as well.

Wednesday, January 25, 2006

things to do tomorrow...

-finsh wheels. this means go to ace and get screws that are long enough and the right size. this also means finsh everything to do with the driving wheels. for example, CHAIN. do we still have a chain cutter? ACE again?

-work on mounting turret, if we dont have the materials for that, we can work on...

-electornics mount. i'm thinking poly carb. i really like the velcro from last year, but with poly carb we have the screw-in option and the velcro option. maybe a thick piece with nicely mounted electronics?

-box for camera...again, would polycarb work for this? sounds good to me, but what do i know? it would have to have some sort of anti-glare/anti-reflection material on the inside. yup.

STUFF we need to GET tomorrow...

(This is basically EM's list)

2'x 2' x 1/8" STEEL PLATE for underneath the turret (to mount it on)

5 ball casters to support the turret and make sure it yaws nicely (5674K51)

2' x 2' x 1/4" aluminum sheet

OR

2' x 2' x 1/2" MDF for on top of steel for the actual turret.

long metal hollow poles. about 45" tall. for holding shower curtains full of balls up. mcmaster or allen steel?

6535K31 - Perforated square steel, like swiss cheese, only less smelly 23.72/6'

6582K19 - square steel, 42.96/6'

6566K526 - rectangle - 43.23/6'

how thick does it need to be? em? j-rock? anyone else?

i'm leaning towards the cheesey one, b/c i just looked back at the rectangle and it meets aerospace and military specifications. i don't think it needs to be that heavy duty

none of them say how heavy the material is at mcmaster. ok, yeah

You guys rock

Goodbye, Thor... ::tear::

today we...

Pressed bearings into wheels with the help of emily and jimmy at ideo, and also found that we are 4 bearings short! (2 wheels are missing bearings) so emily the magnificent has ordered them.

CHASSIS!!!! CHASSIS!!!! CHASSIS!!!!!! (you KNOW)

once we got the bearings in with the arbor press, we came back to casti and got working on the chassis (haha...casti...chassis?! get it? it rhymes! yay!)(click)

we have mounted the transmissions and mounted two of the wheels on the chassis...which was harder than it sounds because we couldn't find the screws, didn't have enough couplers, and didn't have enough sprockets, so we stipped Thor of screws, cuplers, and sprockets (basically we took everything but the wheels and the grime)so Thor is now looking very disshevled but he knows that he is being put to good use. think of it this way, he's living on through our new robot...which we still need a name for.

yay for julia's mom, debbie, who came to chaperone us so j-rock doesn't have to live at castilleja. she also brought chinese food...yummm...thank you beaucoup!

also yay for doug who stopped by a little before 8 to help us out with questions and stuff

and TRIPLE YAY for ROBOTICS and our hot new chassis...

Tuesday, January 24, 2006

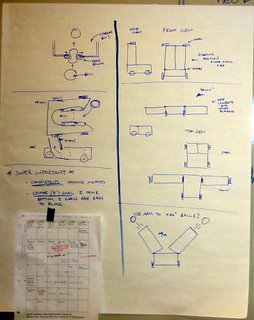

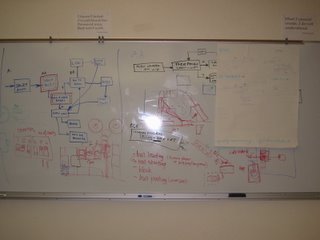

Tuesday Build (the diagram on the floor)

If you've read Chrissy's post, you'll know what I'm talking about. Just in case you don't want to get your butt over to the science project room.

If you've read Chrissy's post, you'll know what I'm talking about. Just in case you don't want to get your butt over to the science project room.[Click on the image to the left to enlarge it. After that, you might have to hover your cursor over the image for another 'enlarge' button to show up.]

A few things that we've been thinking about and stuff to do:

1. Wednesday (that's tomorrow), January 25, with 27 days left. IDEO shop 5:00 pm sharp. Bring skyway wheels and the 3/8" bore bearings that need to be press-fit into the wheels with the arbor press. Once you have the wheels with the bearings pressed in, you can start assembling the chassis. Leave out the middle wheels until Thursday - I have two more wheel sprockets coming in for you from IFI robotics. You can definitely start laying out the approximate amount of chain needed.

2. Thinking turret, yes! So Chris made a good suggestion that we could probably mount the motor to drive the turret directly. I think this is a good idea, but see my qualms below (mostly about gearing things down and being able to sense the angular change with our GTS). Less parts and thus less things to break. We'll need to plan accordingly i.e. probably build an adapter plate to mount the shaft to the turret. For now, I suggest we procure the following:

* 2'X2' 1/8" thick steel plate for the base (nice and heavy, and a hard surface). We'll bolt the motor to the plate from the underside.

* 5 ball casters (get one extra) from Mcmaster to support the turret and take the weight of the turret off the shaft off the motor (the motor should only be driving axial loads). The part number is 5674K51. Thanks to everyone who helped to figure what this widget was called!

* 2'X2' of some material for the turret. I say we can do 1/4" thick aluminum sheet or perhaps even easier, 1/2" MDF (particle board material, like the stuff that Bud used for his coolio prototype).

We might want to get some FLAT steel sprockets from Mcmaster, just in case we don't want to drive the turret directly. We can drill out holes to make them even lighter. I think mounting flat sprockets is much easier. Steel because Sophia reminded me that we need a ferromagnetic material if we're going to try to implement gear tooth sensors. As well, we might need to gear down the van door motor to run it slower!! Type in 'Steel hubless plain bore flat sprocket' at mcmaster to see what I mean.

3. Finally, blah blah. Actually, more important than that. Chris asked for some specs on the van door motor and it is biased. From last year's 'FIRST Guidelines' booklet, I find the following on the Van Door motor:

CLOCKWISE: Stall torque 34 Nm @ 44 Amps; No Load Speed 75 RPM

COUNTER CLOCKWISE: Stall torque 30 Nm @ 44 Amps; No Load Speed 75 RPM

Not a big deal, but what I read is that right now, you get a little more than 1 full rotation PER SECOND! That's 360 degrees in less than a second. We want to scan a field of view of 45 degrees for a total of 90 degrees - that would happen in 1/4 s! Eeek! Okay, that's at no load, but still!

Chris or Doug, I suspect if we gear down the Van Door motor 2:1, we'll hit the middle of the speed-torque curve, get max power, while slowing down the panning of the turret to something reasonable?

Okay, see you tomorrow at 5 pm at the IDEO shop!

- Emily

tuesday -design

-taped batteries

-design specs

-go into the project room and look down on the floor notepad for drawing and design.

turret, mounted underneath (no chain required)

for support, roller balls (kind of like ball bearings)on poly carb, on top of either steel or aluminum.

yes! today was really good!'

thanks to chris, sara,kris, and emily for comming!

hoo-rah!

more later as i have an essay to finish...haha

Get ready to rumble some more!!

Looks like you guys made some great headway yesterday (and dude, I totally wrote this post before I saw Chrissy's Schtuff)! I hope a Mcmaster order is going in today.

Are the following items on your list?

- Timing belt pulleys (yup)

- Timing belt (yup)

- Wheel or drive roller (duh)

- Shaft to support the output pulley

- Bearings to support the output shaft (remember you need them on both sides of the wheel)

- Shaft collars of the right bore diameter to affix the pulley to the output shaft

- Shaft collars of the right bore diameter to affix the motor pulley to the motor shaft

- Long 6" (10-24?) bolts for the mini-bike motor (there's one short one long right now . . .) to affix mini-bike motor to frame

- Any other items for your setup?

Alecia can be of great help to you now. Please consult her for:

- Shaft diameter of the mini-bike motor (she can pull up the file and tell you the radius and thus diameter)

- Check bolt size and thread pitch for the mini-bike motors

Finally, please start assembling the chassis soon!! Programming needs some time to tune their code to the dynamics of a six wheel chassis! With all the parts in hand except for 2 wheel sprockets (as we learned from Team 115 on their setup), assembling the chassis shouldn't take more than 1-2 sessions! Programming would love to be able to NOT be driving around Thor's big behind and start coding for this year's robot chassis instead!!

We're officially at 28 days gals!!

Doing well, with our collective understanding of the need for contingency plans ;)

Em

Monday, January 23, 2006

GET READY TO RUMBLE...

ORDERED THE AIR DUCT STUFF TO FEED THE BALL INTO THE LAUNCHER WITH

ORDERED THE SPINNING WHEEL FOR LAUNCHING THE BALL

ORDERED THE BELT IN ORDER TO SPIN THE WHEEL IN ORDER TO LAUNCH THE BALL

ORDERED THE PULLEY IN ORDER TO MOVE THE BELT IN ORDER TO SPIN THE WHEEL IN ORDER TO LAUNCH THE BALL!

(p.s. we decided on a belt instead of a chain because it's safer. i.e. if a chain is a little bit off, it will slip and come all the way off and flying into something at a large velocity. Ouch. if a belt is a little bit off, it's just a little bit off. b/c the wheel is moving so fast, we decided this would be a good thing)

(p.p.s. we also decided on ONE vertical wheel. launching from the TOP)

i will say that again.

WE HAVE DECIDED ON ONE VERTICAL WHEEL THAT LAUNCHES BALLS FROM THE TOP.

we have also decided that the center of the wheel is about 3 feet off the GROUND, 2 feet off the TURRET. this is non-negotiable. we have already ordered the belt for this lenght.

tomorrow we might take a trip to a hardware store. we will also finish up DESIGN SPECS. (i.e. finish materials list, sizes of materials, where to get them, etc.)

wednesday we'll build and finish design specs (if in case some odd thing comes up and we haven't finished them already (which we totally should)

thursday we'll send some of you to IDEO to press bearings into the wheels. the stuff we ordered today will probably be in by then so we'll be able to do more exciting build stuff.

welcome my friends...hope you have some time to spare... because we have just entered upon the building phase.

YEEESSSSSSSSSSSSSSSSS!!!!!!!!!!!!!!!!!

(heads up, first weekend in feb. there is no robotics. we will all be FOMFing, you should too...)(ps. SF library KICKS BUTT!)

Sunday, January 22, 2006

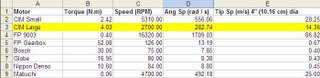

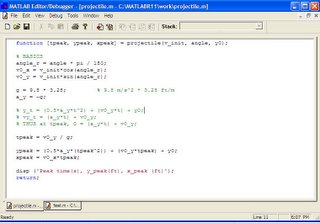

Through the hoop with 12 m/s, 30 degrees, 21 feet away

AND CLICK ON IMAGES BELOW TO ENLARGE AND READ THEM.

Math and physics is cool. Make me happy by at least attempting to be interested in figuring this out theoretically?

If you back out what Team 358 did, here is what you get:

CIM mini-bike motors give you an angular speed of 2700 RPM which equates to a tip speed of 14 m/s (As a comparison, your prototype with the transmission gave you an angular speed of 423 RPM which equates to a tip speed of 2 m/s - that's why it didn't go anywhere). Since the maximum speed allowed for balls leaving the field is 12 m/s, even with losses, this motor has a high enough torque in the range of output speeds that we need to be appropriate (please see excel spreadsheet below – as derived from Sophia’s motorspecs.xls).

Then you crank it through the projectile motion equations and you learn that, well, at 12 m/s, you can shoot the ball from 2.5 feet off the ground at a 30 degree angle, from 21 feet away (that’s pretty much 6 feet away from the center line (remember the field is 54’ by 26’), you will get it through the hoop, smack center. That’s if you have a clear line of sight.

Let me repeat: YOU WILL GET THE BALL THROUGH THE HOOP WITH THESE PARAMETERS

v_output = 12 m/s = 39 feet / s

height of muzzle = 2.5 feet

angle of muzzle = 30 degrees

horizontal distance from goal = 21 feet

See equations below:

Yes, this is no joke. Again, it's very clear that it is a solid solution that the veteran teams have already proven out. Let’s put our efforts into building a solid, accurate, robust shooter. There will be lots of accurate shooters this year. Let’s figure this one out.

- Emily

Saturday, January 21, 2006

the paparazzi is coming to get you

oh and, btw, alecia, those pics on angelfire look good. thanks for taking all of those and putting them up. maybe we could get more of programming and animation?

http://www.angelfire.com/planet/robotworld/casti_robotics/

and for the rest of you - watch your back. alecia is armed and dangerous with a camera.

*muah*

(+j-rock)(and ed)

we PROTOTYPED today!

yay!

We (mostly Kersten and Juila) built an awesome prototype of the two wheels horizontally from the transmission motors and the 2 wheels that Kersten, Aditi and I got this morning (7" diameter, about 1.5"thick.)it kicked butt.

also yay for Diti and Jen who got screws! woo-hoo

from the prototype we concluded

-the wheels will have to be much closer together than where we put them, the ball is really squishy and the more of it touching the wheel, the better

-we will not be using the transmission motors for the spinning wheels. They are too slow. I'm pretty sure we will use the CIM mini-bike motors. Bud and his infinite genius helped us get the funky top off the top of that thing, but we're still not quite sure what to do with the screw that is sticking up. I want to cut it off, because if we want to put anything on top of it, i.e. a gear, we will need the space . I'm not really sure what you'd use it for. But I could be completely in the dark. Emily? What do you think about this?

PRIORITY

vertical or horizontal?

-Since em mentioned the very good point that other robots could just sit and block us, I'm kind of thinking a vertical wheel because we could have it up higher and it would only be one, where as the 2 horizontal wheels i have trouble picturing higher up on the robot. hmmm...

ok. that's all except that I am having trouble finding a place that sells solid rubber wheels that are about 5 inches wide. boo-hiss.

last but not least,

a shout out to j-rock, who is always here (by here i mean at school) and lives far away. yay for him!

i like cake. i hope you guys do too... :)

Shooting from low, what happens if you're blocked.

It's like Chrissy or me trying to throw a basket ball over a 7' tall Yao Ming.

Do we want to give ourselves the best chance of having a clear shot? If so, it makes a difference to be taller!

Okay, now for bedtime.

Em

Kooky looking for now, but not for long . . .

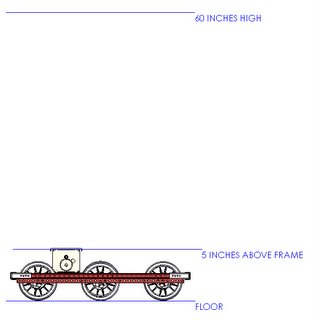

Food for Thought: Dimensions

- Structural Frame: FIRST 2005 Kitbot (see the .IGES files?)

- Kit of Parts: AutoDesk Site login: (public)

The pain in the ass part was having to install Autodesk Inventor just to convert all the inventor .ipt parts to .iges so that I could import them to Solidworks.

Here's a reminder of scale. Dude, yes, 60 inches in height is a LOT more than we think it is. Do we want to take advantage of it? Ain't Solidworks COOOOL?

Friday, January 20, 2006

"Rubber Ducky, You're The One..."

advatages of vertical wheel or horizontal wheels. will prototype tomorrow.

for the mesh NETTING on top- suggestion - use a clear plastic shower curtain, or one with rubber duckies or something cool and shower-curtain-like, so it's clear and strong. that way things won't get caught in it. yay.

we also discussed stuff, like what our angle of freedom on the turret should be, we're thinking around 120. yeah.

we're pretty sure that the angle of the shot WILL NOT MOVE. that means that it will YAW ( <----> )(side to side) but not PITCH (^ v )(up and down)

TOMORROW = PROTOTYPING

come prepared

we will:

-prototype vertical and horizontal wheel design with crap pnumatics from ace.

-test which motor we want to spin the shooter wheels

-press the bearings into the wheels (IDEO)

-put wheels on chassis.

ok my brain is dead, if i remember anything else, i'll post it.

that's a lot to do, and we can spilt up and do different things. get ready!!!

Thursday, January 19, 2006

"I'd like a side of fries and a fully functional robot, please..."

large goal = finished! (huge and in the gym, go check it out! it looks great)(also thanks to Eric (sara's bf the swedish carpenter)for helping us put it together!)

small goal = (mostly) finished!

Robot- jen, sophia, and I checked out the pitching machine over by the softball field today, and it actually looked pretty good. But instead of using a pneumatic tire (which we don't want because it would have to be the EXACT same pressure each time we shoot the ball for our shot to be consistent. Any variation in pressure means a variation in where the ball ends up. Not good)we were thinking maybe a solid rubber tire. (p.s. this is all if the wheel for shooting is vertical)Another thing to keep in mind is that on the pitching machine, the width of the wheel was about the diameter of the softball, so we'd want OUR wheel to be about 7 inches in width.

Does anybody know where to get a large-ish wheel that has a width of 7 in? or 6 in? 5 would be streching it. or in this case contracting. (click) Emily? the robot store doesn't have very many wheel options for us as far as i can tell, and Mcmaster is huge, where do we start looking for something like that?

We're going to PORTLAND because...

it will give us practice with the robot. more compition means we get better! Also, since the portland regional is before SVC, we'll be able to fine-tune our skills so we can use SVC to show off. :) we also have confidence that our PR team will get us some money. soon.

because my mother is a lead parent rep, (she meets with JLo and Blair once a month)she will be arguing on our behalf for money. just for the update, her argument is "why are we sending people to china and india if we can't even support our own science and technology programs? especially robotics!" good question mom.

Random thoughts (actually not too random but whatever)

hoo-rah for Mr. Berger and his amazing cooking skills.

wow upside down is mom

Doug's shelves make me happy every time i look at them

build team rocks

sleep lots this weekend, because soon you will not be gettting very much.

More Inspiration: Foam Peanut Dispenser

Benchmarking Ball Shooting and Pitching

Dear build team - perhaps the reason why I am bringing the vertical positioning on the table is because I've seen it done before, in baseball pitching machines, and in various mechatronics and robotics projects at the college level around the country. I guess I feel more comfortable for your success knowing that we're scaling up a proven concept, rather than going with our gut.

Here's the evidence that I've found from various sources:

1. The electrical engineering department at Stanford had a tournament one year that involved many launchers of this sort. For a photograph of the real robot, check out THIS PAGE.

2. Undergraduate students at the University of Illinois Urbana Champagne (an excellent engineering school) also solved a similar problem the same way. For more information about their task, check out THIS PAGE.

3. And finally, last but not least, here's a reminder of what a baseball pitcher looks like.

Help me prove out that your concepts also have high potential for success!

Yes, there are many nights I can't sleep because of you . . .

Em

Brand New Shelf!

Wednesday, January 18, 2006

wheel suggestion

http://www.robotcombat.com/marketplace_wheels.html

YAK wheels-large

$20 each

or the

NPC DRIVE wheels with delrin hubs

8"

$23.50

DON'T PANIC

HI

we've decided to use the wheels we were given as opposed to buying new ones. Maybe we can beef up the traction in the ones we've got. kersten suggested buying rubber. Sounds good to me. If anyone knows how expensive rubber sheets can get post a comment.

Doug brought us KICK BUTT new shelves. Doug rocks.

another lovely dinner from the Kasturia family...and fabulous cake...yummm...

on to real robot stuff.

we're mounting the turret about 5 in above the base of the chassis, so it doesn't hit the wheels.

CIM AP801-005 motor for spinning ball launcher wheels

radius: .08m = 22m/s

radius: .09m =25m/s

the .09 radius is better. We're going to use it.

18cm ball 18cm

[_______](------)[_______]

the only thing is we need a way to secure the motors ON AN ANGLE and make sure that THEY DO NOT MOVE. THIS MEANS SECURING THEM SECURELY. if we can't do that, (b/c there are appearently funky gyro forces at work) emily suggests vertical-izing the wheels. I am skeptical, but what do you all think?

ok. if i forgot anything, let me know.

How'd they do that? Driving Six Wheels . . .

By choosing to do six wheels, I had some serious concerns about being able to align all the wheels in the same plane. That's really important. So now we have one potential answer that's pretty good.

Often times, we open our eyes a little wider beyond what we think we know and can guess, and all our answers come flooding in.

Team 115 is here: http://www.mvrt.com/index.php?z=clear

It'd be awesome if they could help mentor us a little bit.

Tightening our belts

We have some big decisions and a tight budget this year. I *really* want you to be able to justify parts that you might want to buy but not necessarily need - you guessed it - I 'm talking about the chassis wheels. In my opinion (and that's just my opinion so take it with a grain of salt), these are wants, whereas things like, uh, the launcher wheels are NEEDS.

I apologize that I drummed up so much excitement about the traction wheels but at that point, there were a few pieces of information that I did not know, including what we had in the bank.

Chrissy and Kersten, the 6" wheels will cost quite a bit more than $30.00

Here's the site: http://www.ifirobotics.com/robot-traction-wheels.shtml

Base 6" outer diameter wheel: $49.95

Tread: $3.95

Wheel Sprocket: $12.00

That comes out to approximately $66.00 per wheel.

And a total of 6 X $66 for the entire chassis: $396

(And yes, we'd return the sprockets that Jon ordered on Monday for the current wheels)

We need to think and reflect on this if we were to spend $400 on the wheels alone. I mentioned to Sophia, that given our current financials, we should work as frugally as we can. This ties in with the Portland trip and how much of that we can fund.

I would very much like to build this robot for about $750 and we can, given what I know today about the money we have.

Let's talk later.

Em

Tuesday, January 17, 2006

Goals

Jez says we can put the goal in the corner of the gym that is near Chrissy's locker. We should probably not do that today, though, because they will have Al Gore in there.

Yay!

Kersten

Monday, January 16, 2006

35 Days Left!

Here's a reprise of the list of stuff:

Build Field Elements (ALMOST DONE, YAY!)

Determine chassis structure, layout and mobility (GETTING DONE)

Design and build the chassis support structure (THIS WEEK?)

Design and build support for the electronics

Design and build an encasement for the battery

Design and build any other support structures for motors and other actuators

Design and build all the signage that is necessary

Design and build the scoring device (i.e. launcher and loader)

And one more really important thing:

Design and build armor for the little fragile $200 camera.

Yup. Geezus. I'm doing CMU camera bedtime reading and I realized that if a 7" diameter foam ball goes flying at 12 ft / s into the camera, it'll begin its existence as a useless hunk of plastic. Wait, maybe if it does die, we can turn it into J Rock's pet rock.

Good night fellow bots,

Em

Monday

We'll meet early tomorrow because Al Gore is talking at 7. Time will be posted soon.

Cheers!

Kersten (and the new peanut gallery--aka Julia)

Sunday, January 15, 2006

Six wheel drive: What other parts do you need?

How many more 21 tooth #35 output sprockets do you need? (Hint: We talked about needing a really thin sprocket for the middle set of wheels – don’t worry about that detail for now. Just think about how many more output sprockets you need in general).

How many more 28 tooth #35 wheel sprockets do you need?

How many CIM motors do you need?

Finally, what’s it all going to cost?

Remember that you won’t be able to complete the chassis without these parts and that parts always take a good amount of time (atleast 2 days) to be purchased and shipped! So plan for that!

PLEASE let J Rock know what you need before NOON on MONDAY! If you can tell him that, there is the potential to get all the parts shipped to you by Wednesday!

All the information about the parts can be found here: http://www.ifirobotics.com/ifi-store.shtml

Good luck Build Team!

- Emily

Saturday, January 14, 2006

Saturday is cool

Built: Parts of center goal, to be assembled when we figure out where we're going to put it (monday). New key for saw/sander, so we don't need to keep moving the yellow one to use them. (It's purple and is currently in the saw).

Put up the glasses holder in the shop that Bud gave us.

Put a metal and polycarbonate blade on the bandsaw after breaking the wood/polycarbonate saw due to a weak weld.

Meant to get to assembling the chassis w/ six wheels, but didn't get around to it. Now we have that to do Monday when we meet from 10-3.

Turns out we aren't missing a fourth motor, it never existed. We'll order it.

We have taken up WPS Robotics on their offer to sells us some of the Poof basketballs that we'll need. They've already ordered, but have some extra, and with shipping they'll cost about $7 each.

We also built the box for the green light that'll go above the center goal, and painted a red circle around the center goal so we can see it. Yay.

We have also decided that J Rock needs a pet rock. Anyone who would like to donate theirs should contact Kersten and Chrissy. We will conduct interviews with the rocks to maximize personality compatability with The Rock (yay he definitely needs a pet rock because it's his name and also he's probably lonely without his cat).

That's all the exciting stuff, except that Bud came and helped out with a whole ton of stuff and is totally awesome and now some of what we did actually works. Huzzah!

Also, bear in mind the size of the screws you're using when you're screwing stuff together. Otherwise bad things may happen.

And in a gesture to the Department of Redundancy Department, we'll say again that we have decided on a 6-wheel and 6-wheel-drive robot.

Cheers!

Kersten and Chrissy

Friday, January 13, 2006

Friday.

First things first

SATURDAY-10:15-2:30 OR 3

MONDAY - we will meet, and tomorrow we'll talk about the best time for everyone, I am suggesting 11-2, but that's not set in stone.

So today we painted the crate! It's finally done!

we also decided DEFINITELY on a 6 WHEEL, 6 WHEEL DRIVE CHASSIS

6 wheels provide lots of traction, which we need, and 6 wheel drive enables us to have all 6 wheels powered(attached to the transmission. This is better than 4 wheel drive because then the middle ones would not be powered and it would basically turn into a 2 wheel drive system.

Alecia and I did one transmission box, (using the directions from last year :) and Kersten measured out and we all helped cut the hole in the largest sheet of plywood for the center goal.

TOMORROW- SATURDAY

-build field elements

-finish transmissions (without the sprockets though, b/c we need two more for the 6 wheel drive design-we'll put them on later)

-Finalize robot design!!!

I know this is a lot of stuff but I think you guys are up to it!

if we get going early and work hard we'll finish in no time. The goal stuff is all cut save for one piece and the transmission is pretty simple to do. The hard thing will be finalizing the design. Where do we want the "funnel" to lead to? Do we want some sort of ramp bringing balls down? What is the right velocity for the two-wheeled shooter? Dimensions? Etc.

everyone give Emily, Doug, and Mr regimen hugs tomorrow, they are so badass and they rock. They also enable us to actually DO everything we do.

yayas!

-chrissy

Thursday, January 12, 2006

Build gets cranking

Continuing on the field element build dive, Chrissy and friends finished cutting all the lumber at Castilleja with the new miter saw with the laaaaaser. Fantastic work there. Jen and Aditi joined Emily and Krysta (another IDEO-er) to cut all the plywood to the right size for the field elements. The biggest challenge was certainly getting the dang 15 degree edge on the ramp today - talk about serious belt sanding efforts!!

Kersten's dad George so generously donating his time and good (bad?) humor to the effort - picking up stuff from Minton's and then picking up stuff from IDEO and then helping Julia figure out what the field element drawings were trying to communicate. Now we all know that R5 with an arrow means that the curve has a radius of 5 inches!

I think we're in good shape Build!

Tomorrow, when you meet from 4-7 pm, work on getting the field elements put together. It would be great if Mr. Rockman or someone was there to help guide you in the process of putting things together. Nevertheless, you can still cut out the circle for the center goal and the side pieces with the jig saw while you wait.

The other thing you can do: Chassis stuff. A few of us really pushed for having six wheels. Can we all agree on that? I know some of you haven't been at the meetings as consistently - but it's not hard doing six wheels and a pretty good idea. If you are concerned about this, please voice your opinion here on the blog and Ed and I and other members will be able to respond.

If you want to bring the wheels to IDEO to press in the bearings on the arbor press, please let me know. I suggest just sticking with those wheels for now. We can totally switch them out later if we have time.

Is that good build team? Is that enough to do tomorrow? I'll be with programming and getting the computers set up. We're having some serious compiling issues, so that's where I'm going to dedicate my time tomorrow.

Thursday,- ready to lock and load

today was a pretty good day...

Alecia and I cut all the support beams for the high and low goals, while Emily, Aditi, and Jen measured and cut all the faces for the goals (esp. important for shooting balls through :) ). Kudos for Kersten's mom who brought their SUV for transporting those Big pieces of pylwood that Jen Diti and Em cut at IDEO.

Kersten and Juila are on their way to becoming master carpenters and decoders of confusing instructions. Kersten used her wits when we found no string in the shop to use a piece of wood, drill a hole through it, and use it as a circle template. so all we need to do now is jigsaw it out and we have a goal! YES! Juila found that the FIRST engineers are not so good at making instructions for people to easily understand. why they only label where to put the screws and not where to cut is beyond me.

Get ready for Crate painting tomorrow around 4 (yay! come with creative ideas for what we want to put on it and clothes that you don't care too much about...haha

Also tomorrow, we will start putting together all the pieces of the puzzle and connect all the seprate pieces of wood we have to make a kick butt high and corner goal!!!! yay!!! if we finish really quickly, we might even be able to start on the frame of the chassis! I remember deciding 6 wheels but we can talk about it tomorrow, possibly during the crate painting? Chassis design-framing, wheels, and such, will be continued on saturday

As a side note, Julia and Kersten have mad dance moves. Never even attempt to challange. or imitate. or anything. It's truely an amazing sight. :)

yay for ROBOTICS!

Once last comment, please please PLEASE be on time for our meetings. we start right away (at 4 tomorrow.) THANK YOU!!!

-chrissy

Ok, wtf.

So I guess I've only been posting in the build team's blog.

Anyways, is there a way to look all the blogs together by date?

Also, can we get a phone/contact list distributed by email or posted here or something?

Thanks!

Ed

Wednesday, January 11, 2006

Wednesday- We're good to go!

Shirin brought awesome food today. hannah and i estimate that we consumed about 2,000 calories just in chocolate cake...yummmm....

THE CAMERA IS READY TO ROCK AND ROLL!!! we finished the stand and hooked up the servo motors. it moves really awesomely. Em, is it really bad to move the stuff connected to the servo motors? you can hear it turn but it doesn't sound terrible. although last year the VAN DOOR (like a car)died and none of us really knew. we kept the spinning to a minimum today though, just in case... :)

thanks to J-Rock for comming with us to the Home Depot to buy wood and screws. if anyone can think of a more original nickname let me know, appearently it's not "original" enough (j-rock was his college nickname)haha.

i'm pretty sure we have decided on the "spinning wheel" design for shooting balls. so get read to "aim high"!!!

-chrissy

VICTORYYY!!!!!!! Solid...WORKS!

-Alecia

Another spinning launcher (that spits out pucks)

Here's the website:

http://me118.stanford.edu/pictures/Win02Projects/mmmLED/index.html

Here's the blog:

http://me118.stanford.edu/pictures/Win02Projects/mmmLED/ideas.html

IMPORTANT: Are we missing anything from KOP?

JR

Make no little plans . . .

- Daniel H. Burnham

Wednesday CARPENTRY DAY

Here’s what were going to do. Wednesday is going to be an awesome build day. Jen’s bringing the van. I want you guys to pick up all the LUMBER and use your RADIAL SAW (do you have parent supervision or atleast a buddy?) to cut the lumber to approximate lengths. Remember to add like ¼” to every length since the radial saw will chew through material the thickness of the blade.

Emily will go to Minton’s Lumber in Mountain View either Wednesday or Thursday morning before work to pick up 2 sheets of ¼” plywood and 1 sheet of ¾” plywood and half a sheet of ½” plywood and have the sheets cut to approximate sizes for transport and ease of cutting through the table saw at IDEO. If you haven’t noticed, it’s a pain putting a sheet of 4’X 8’ plywood through the table saw!! SO DON'T BUY ANY PLYWOOD SHEET!

Go to Home Depot and buy the material, and cut it to rough lengths on the radial saw. We'll get the sheet cut at IDEO on Thursday and assemble the field elements!

Fasteners to purchase:

2 boxes of #7 1-5/8 in deck screws (1 lb. boxes)

2 boxes of #8 2-1/2 in deck screws (1 lb. boxes)

1 box of 1 in. fine thread drywall screws (package)

CORNER GOAL

Purchase the following:

5 pieces – 1” X 3” X 8’ (#2) SPF Lumber (or wood strapping)

Measure out and cut on radial saw:

* 2 pieces that are 3’-11” long

* 1 piece that is 3’-9.5” long

* 2 pieces that are 3’-4.25” long

* 4 pieces that are 2’-11.25” long

Remember to mark the length of your wood pieces with a pencil afterwards so we can keep track of the pieces!

CENTER GOAL

Purchase the following:

2 pieces – 1.5” X 1.5” X 8’

3 pieces – 2” X 3” X 8’

2 pieces – 2” X 4” X 8’

3 pieces – 1” X 3” X 8’

Now, measure out and cut on the radial saw . . . you can figure this one out from the drawings at the back of your manual. Remember to mark the length of your wood pieces again, maybe even number them with the corresponding part number from the drawing!

Tuesday, January 10, 2006

finally

http://www.angelfire.com/planet/robotworld/casti_robotics/

-Alecia

Week One Blues

There are definitely a few things I'm worried about, but I'm sure we'll be able to solve all these issues soon enough.

1. Building the field elements: This year's field elements are substantially harder to build and house. If OUR PRIORITY is to build an accurate and robus ball shooter, we NEED to have the center goal built with the lightbox on the top of it, and mount it somewhere such that we can have the robot try to track if from 10'-15' away and shoot. The center goal is 11' tall with the lightbox on it. FINDING A PLACE for this and building this component accurately is a MAJOR PRIORITY.

2. Vision System: The reason why delving into the vision system worries me (even though we'll need to do it if we want to be a shooter robot) is that the programming team doesn't have the basics down yet. Delving into the camera, which also presumes a lot already in the way it is set up, means we need to understand the code FIRST and then start modifying it for our own means, like removing the yaw motor and fixing the camera to the shooting device and having it move like a turret.

3. The increased complexity of multiple motors and multiple sensors. Last year, we had one motor and even with one motor, we had mounting problems. That's really scary. We will definitely need sensors this year and likely more than one motor. So we need to start learning how to mount motors, sprockets and chain well. Remember when the arm motor wore down last year and when the set screw kept shearing. Think about that pain, multipled by like four, if we have four motors that we don't take time to think through when mounting.

On the SUNNY SIDE, we have a GREAT BUILD TEAM this year and GREAT HARDWARE / SOFTWARE people. We just need to work together. I'm glad we went through the kit of parts together again today. Kudos to Julia and Chrissy for starting to assemble the camera, and to Jen and Chris for making the 'rough and ready' spinning launcher prototype!

Wednesday - build team is going to pick up materials for the building elements. Jen is going to bring the mini-van and Em is going to get together a condensed list of materials to build the center goal, the corner goal, and the lightbox.

Lovely ladies,

Em

Tuesday

So what happened tonight?

Kersten

WE'RE GONNA KICK ***

-we went through a lot of stuff today.

motors- we have 10 that is A WHOLE LOT. much to work with. the hard part will be picking the right ones for the right movement. we will probably end up stealing 2 of the CIM motors off of Thor so we can have a 4 wheel drive system (Kersten-this means you and me need to talk) with 6 wheels. that leaves 8 left for whatever. think rotating wheels, levers, something to shoot the ball out with if not levers, etc.

electronics- EM gave us a quick overview on what the electronics we have are and what they are used for. ex. programmers might not need to do PWM code for all the motors if we use a regulator (is that right? the little black thing with things on each end that look like they'd plug into the wall but don't)

camera- we started putting it together today (we didn't get very far) but it doesn't look too complicated so we'll hopefully finish that up tomorrow night.

structural design- HUMAN LOADING AND SHOOTING HIGH (top goal) will be the things that we are focusing on this season. hence the camera. low goals are out because of defensive monuvers that could block them altogether.

Jen and Chris put together an awesome (but scary looking :) (but cool)prototype for the shooter with the spinning wheels (pitching machine style). there are still bugs to work out in the design, (angle, momentum, etc.) but that's why we prototype! it's a good jumping off point. you guys rock.

The most fabulous Doug got us a set of tools for christmas! THANK YOU!!! and if anyone sees him, give him a big hug, not only for the tool set, but also for his programming and anything to doing with engineering prowess.

Jen has volunteered to get stuff for building the hoop. yay for her.

please Please PLEASE be on time to your meetings guys. we only have 3 hours, which seems like a lot until you find yourself still in the project room at 8:45 thinking, "man, where did the time go?"

i would love it...

Also, if you aren't comming or you are going to be late, please let me know. i will not remember if you just talk to me. send me an e-mail. send me a text message. put a note on my locker. it all works. i won't get mad at you for comming late if you tell me beforehand. thanks.

i'm kinda nervous about this competition, but I also think we can KICK SOME BUTT. the farther we get into it, the more fun it is. you can't imagine how funny things are when you haven't slept more than 4 hours in a week. :) so let's give it our all these next 6 weeks so we can beat the (*cough*) out of 254

ok that's about it.

-chrissy

Monday, January 09, 2006

Critical for Build and Brain to work together

This is seriously a tough game guys. The more I write, the more I realize all of build and all of programming need to sit down and hang together.

Here's the most current programming blog entry:

http://gatorbotics-code.blogspot.com/2006/01/strategy-autonomous-and-coding.html

With all this auto-targeting stuff that we want to do, build and programming have to decide TOGETHER what they want to tackle and what the constraints are i.e. do we hold the shooting device at a fixed angle? If the shooting device needs to move at all i.e. a turret on a tank, build needs to coordinate with programming and vice versa to make sure that 1) we can actually build it and 2) we can actually code it to do what we want.

And here's to the tank!

- Emily

Em’s Monday Night Build / Strategy Thoughts

Ball Loading: You can do this by human or by having your robot pick them up.

For a human to do it, the disadvantage is tha you HAVE to be at your loading zone in order to load it up, and please look at the FIELD ELEMENT drawing (click here) – you might need a sharp shooter and a big basket for that person to aim into. The advantage is that it is a passive system and easy to build.

For the machine to do it, you need to invest time in building a robust system. And then you may need to figure out where the balls get queued up after they get fed into your robot.

Ball herding: You can definitely push the balls around, but you can’t have something on your robot that looks like a wedge (see rule

Ball hoarding: There are a finite number of balls on the field in every match (like 80). What happens if you built an awesome ball hoarder and were able to DOCK with the strongest robot on your alliance and transfer the balls to that robot?. I know this is a defensive strategy, but it can be an offensive one too.

Ball dumping: Once you have collected a number of balls, do you plan to try to dump them into the corner goal? The advantage of this is that this can be as simple as lifting up or dropping a wall. Not a lot of mechanisms that you need to design robustly.

Ball shooting: Okay, lots of talk here. This is a tough one. We NEED to understand how the CMU camera works and how it interfaces with the robot. I mean, this is enough to keep ONE MENTOR busy the entire season and I swear by that. US FIRST has already written code for us and has provided us with a ‘Camera Pan/Tilt Bracket Kit’ which means structurally, I’m not sure what it assumes as it relates to the given code. We had some great ideas like making the robot like a tank, and fixing the angle of the shooter and only allow it to spin on a turret. However, the CMU camera package may already presume more than one degree of rotation.

Let’s look into ways to make sure that we can ACTUALLY build this system in a robust way, by putting clear constraints on what we want to do with the camera. Please read the programming / brain blog for more thoughts on the camera.

So here are some potential combinations that I think we would be able to accomplish well (starting from easiest no duh):

- Human loading, strong defensive blocker, ball dumping into corner goals, solid autonomous code for dumping up to 10 balls into the corner goals

- Human loading, ball shooter

- Machine loading, ball herder and ball dumping into the corner goals

- Machine loading, machine transfers balls to subsystem for machine shooting, ball shooting (this is hard because we have two subsystems and a way to transfer balls from one subsystem to the other – we *might* not get this to work at all).

Don’t even try to do everything. If you do, I am NOT going to mentor you anymore because I will die trying to help you out. There are other combinations, but by the end of this week, I’d like you to think about what you want to do.

In terms of mechanisms: All sounds great. My biggest flag is that for spinning motors, you need to remember that they need to be ‘spun up’ to the right speed before you feed anything through it. That means you have to GATE the balls so they don’t touch the wheels before they spin up AND you have to have a loading mechanism to LOAD the balls when the wheels are spun up.

Okay, on to programming blog . . .

- Em

Monday Night Thoughts:

You are awesome, I hope I didn't throw too much on you, but I think a flowchart is a good way to start on thinking about the programming process and loops. That way you know what commands and subroutines you want. You know? Then someone (trust me, you don't want me) can help you go over the "nuts and bolts" of the coding.

Plus, flowcharts are easy to sketch and share. Think:

flowcharts/logic diagrams : programming

design-brainstorm : build team.

Was that an analogy? I haven't used those since the SAT's. = P Scary, in the words of Will Ferrel in Old School "*nnngaahhh!* Sorry, I think I just blacked out for a minute back there."

Build team: Sweet deal. I like the spring cannon/pinball launcher and pitching machine ideas.

Ed's notes and KOP parts

Some Deadlines to Aim for

- Crate Painting (FRI 13 4 pm)

- Build Game Pieces (THU 12 6-8 pm)

- Brainstorm DUE (SAT 14)

Week 2: Jan 16

- Spirit Logo DUE (MON 16)

- Robot Strategy DUE (MON16)

Week 3: Jan 23

- Design Details DUE (SAT 21)

- Start Building Robot

Week 4: Jan 30

- Continue Building Robot

- Driving Practice (SAT FEB 4)

Week 5: Feb 06

- Robot systems DUE (MON FEB 6)

- Start Integration

Week 6: Feb 13

- Integrated Robot DUE (MON FEB 13)

Week 7: SHIP FEBRUARY 21

Wheel based shooter

And one request,

PLEASE PLEASE change your visable name to be just your first name. It's really hard to keep track of everyone on robotics so do us all a favor and make your display name the one your parents gave you.

catapult, pinball machine/cannon thing, two wheels.

with a catapult, we could have a taut net basket to hold the ball. the catapult would start in a raised position and then would be released to launch the ball into the air. fairly accurate, as in it's relatively the same force over and over, so we'd know how much to move around.

with a cannon with a springloaded device, we'd have a chute and a platform inside it. the spring attached to the platform would be loaded (coiled) and then we would release the platform, pushing the ball up and out of the cannon.

with the two wheels, the ball would be launched like something of a pitching machine. the two wheels counter-rotate to launch the ball out. we'd probably need a chute, to ensure accuracy.

the three problems in all these setups:

loading the ball into the start position.

reseting the mechanism - how do you reload the spring? would a motor be strong enough to compress the necessary spring (used in both the catapult and spring loaded cannon)?

releasing the platform or catapult, etc. possibly use a solenoid pin. need some ideas on this, so think about it.

low goals and high goals

so today we talked about different designs

1)for picking up balls

-ball harvester

-scoops up balls/ pushs them into a ball storage area with a paddle wheel type design. it woudl span the entirty of the front of the robot so to pick up any balls that come our way. Hits about in the middle of the ball so the ball isn't pushed into the ground. Possibly could have "protecters" that come out and protect the front "harvester" on defense. i think we've all agreed that this is a good idea.

2)lower Goal and Higher Goal

-we have realized there is no rule against sitting in front of the bottom goal and blocking it for the entire round. ick!!!

therefore, we are thinking more about the higher goal than we were yesterday. catapult? we've definatly said no to pnumatics. We're thinking maybe a spring loaded something...

more later!

*muah*

chrissy

thoughts from the bat

Lots and lots of practice balls?

Greetings Teams:

Poof-Slinky has offered the following option for teams:

For a minimum order of 48 balls, teams can call customer service (800) 329-8697 with a credit card and order the #850 Basketball at the wholesale price of $4 each plus FedEx Ground shipping.

**Important** - in order to get the discounted price, you cannot place the order on-line; you must call the number above.

My time restraints.

First off, let me apologize, I'm not one to give excuses, but let's just say work is keeping me extremely busy.

Thus, I know I won't be able to contribute as much as I did as year, as far as time and commitment, but am glad to help out where I can if you don't mind keeping me around.

This means, that I won't be at the weekday meetings as much, but feel free to call or email or blog your questions. I probably won't be able to do everything you ask, but I promise I'll do whatever I can.

I left a few of my initial thoughts taped to the white board on the left in the project room, I'll try and drop by tonight and see how you're all doin.

By the way, you gals are starting this year off AWESOME! Great job team leaders! Keep it up!

_Ed

Back again from outer space

-Alecia

TranquilityBase=Alecia

-Alecia (by request of chrissy)

Victory!

Cheers!

Kersten

Sunday, January 08, 2006

Food for Thought: MON JAN 9

First things first - Check out this AWESOME prototype of a ball collector by team 360 that they built in 2004. I've listed the website I stole this from below.

So y’all! I don’t think I’ll be able to meet with you tomorrow from 5:00 – 8:00 pm. My plan this week is to meet with you at least on Tuesday and Thursday and Saturday.

Here are a few things you can definitely work on:

** Make sure everyone is plugged into the build blog and can use it. Kersten, I want to make sure we figure out that posting problem for you (eeek!).

** Mr. Rockman will give you two bound and printed copies of the FULL 2006 FRC manual (it’s the fat one). Please at least skim through it. I expect one of you to be snuggling up to it as bedtime reading, familiarizing with the rules. That’s what I’m doing tonight. Take turns borrowing the manual (I don’t want to kill too many trees).

** Gather materials to build field elements: We need to build at least the hoop with the light on top of it if we want to be able to shoot through it. It’s angled funny. You’ll find LARGE printed sheets at the back of MANUAL with all the diagrams. Figure out what you need to buy from Home Depot or Ace to build them – here’s a partial material list: http://www2.usfirst.org/2006comp/AdvanceBuy_2006_r4.pdf. I would be awesome if you can get a teacher or parent to pick up the materials so that we can work on building the game pieces on Thursday night (6-8 pm) @ IDEO.

** And of COURSE! BRAINSTORMING!! Get a pile of computer paper and start drawing lots of stuff! Think about Ball Herding separate from Ball Launching.

Also, Tania had a really good suggestion of looking up stuff that exists in the world already that would be inspirational. Check out these sites:

Ball Launcher Advice: Click here

What a National Championship Team did a few years ago:

http://teamster.usc.edu/~fixture/Robotics/2004Build.htm

Cool Prototypes of Ball Collector (see above) and FRC robot:

http://www.seattlerobotics.org/encoder/200004/first.html

A class I did at Stanford that required shooting stuff out:

http://design.stanford.edu/spdl/EE118/YellowJacket/report_toc.html

And a LOT LOT MORE on the web!!

Good luck! See you on Tuesday! - Emily

Haha lookit me I'm blogging!

WHAT DID I DO TO DESERVE THIS? And why does it say "Gatorbotics Build" on my non-posts?

Gatorbotics Build

posted by Kersten Schnurle at 6:02 PM | 0 comments

OK why isn't the thing letting me type in the body box?

Gatorbotics Build

posted by Kersten Schnurle at 5:52 PM | 0 comments

except all I can type is the title

Gatorbotics Build

posted by Kersten Schnurle at 5:51 PM | 0 Comments

ROBOT Magazine article

http://gatorbotics-friends.blogspot.com/2006/01/robot-magazine-on-gatorbotics.html

your mother posted last night

- (your name here)

or at least until we all know who everyone else is.

ok that's my 2 cents.

GET READY!!!!!

chrissy

Food

prototype...yay!

Okay, so 1) PEOPLE RELAX! DO NOT FRET! WE WILL KICK BUTT! (extra good vibes to chrissy) 2) We got checked today and no one got beheaded. good job. 3)I have these robot pics that I took...but what should I do with them? Can I just...post them here? like this? hmm...no. it takes too long. somebody give me the casti photo link in their spare time, please. 4) Should we bring food for our meeting on monday? 5) How long do we plan to focus on brainstorming? do we have particular deadlines yet or are we just going to kind of go with the ~~~flow for now? (Sorry about the color. trying to get a feel for blogs.)

Saturday, January 07, 2006

Check out the links on the side!

There's a blog for you guys at http://gatorbotics-build.blogspot.com.

There's a blog specific to electronics and programming at http://gatorbotics-code.blogspot.com.

And there's my friends of gatorbotics blog here: http://gatorbotics-friends.blogspot.com.

As well, I've posted some generic links to places like US FIRST and your own website for the time being. Let me know if there's anything else I can link to for you.

Bad-ass Build Blog

Here's notes that I sent to you by email a while back, but still relevant:

Dearest bad-ass robot builders:

First things first - happy holidays! I hope you are all well! Having stuffed myself with turkey and slept until I've built up a wink surplus, my noggin' has started chruning on bot-building thoughts once again.

Y'all did some pretty wonderful things this fall semester: getting new tools, cleaning up the woodworking shop, getting the science project room in order, thinking about chassis and wheel stuff, visiting Alan Steel and spending time with Jimmy learning about the different ways to weld things together!

Yet, the season dawns upon us and it's going to be a wild ride!

There is one big thing I want you to start thinking about (Mr. Ed, please jump in): What are you going to need to do, who is going to do it and when will you get it done? As the build team, remember that you are not working in a void. Whatever you build, the programming and electronics team will have to plug into and make things work. You guys are primarily involved in all the mechanical stuff - but with motors, sensors, electronics, programming and the like, we'll have a really pretty metal sculpture and no robot. Logistically, you will have to make an effort to COMMUNICATE with the electronics folk what you are trying to accomplish, as there is only so much they can make happen for you. As well, you will be in charge of doing whatever is needed to support the electronics i.e. motors need to be mounted and electronics need to be . . . um . . . kept from being set on fire . . . yeaaah . . . hmmm . . .

Perhaps, you can start by making a list of things that need to be done . . . (based on Thor last year, here's a partial list of things that I suspect will need to be done this year, regardless of what the challenge is).

Determine chassis structure, layout and mobility

Design and build the chassis support structure

Design and build support for the electronics

Design and build an encasement for the battery

Design and build any other support structures for motors and other actuators (i.e. pneumatics, solenoids)

Design and build all the signage that is necessary

Design and build the scoring device (i.e. arm)

Design and build any support structures necessary (i.e. motor mounts)

. . . . and what else?

Once you have that list . . . who would like to take charge of each task? Some of you are probably already more familiar with certain parts more than others (like Julia on motor mounts, Sophia on supporting batteries, and Chrissy and Julia on electronics covers). Remember not everything has to be done in series i.e. we don't have to wait until the last hour to make the signage.

And what's your game plan and time line for getting it done?

Remember, we had a working robot 12 days before the ship date last year so at the very least, Julia and Jessa had some time to practice on it. Even then, things weren't completely integrated yet. You might want to aim high and push to finish by the FIFTH WEEK i.e. first week of February, so that Shirin and Christina can work with you to integrate all the electronics and software WAAAAAY before the ship date!

So that's it: WHAT, WHO, and WHEN?