AND CLICK ON IMAGES BELOW TO ENLARGE AND READ THEM.

Math and physics is cool. Make me happy by at least attempting to be interested in figuring this out theoretically?

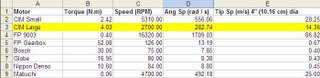

If you back out what Team 358 did, here is what you get:

CIM mini-bike motors give you an angular speed of 2700 RPM which equates to a tip speed of 14 m/s (As a comparison, your prototype with the transmission gave you an angular speed of 423 RPM which equates to a tip speed of 2 m/s - that's why it didn't go anywhere). Since the maximum speed allowed for balls leaving the field is 12 m/s, even with losses, this motor has a high enough torque in the range of output speeds that we need to be appropriate (please see excel spreadsheet below – as derived from Sophia’s motorspecs.xls).

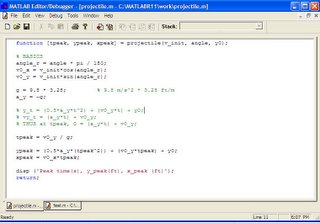

Then you crank it through the projectile motion equations and you learn that, well, at 12 m/s, you can shoot the ball from 2.5 feet off the ground at a 30 degree angle, from 21 feet away (that’s pretty much 6 feet away from the center line (remember the field is 54’ by 26’), you will get it through the hoop, smack center. That’s if you have a clear line of sight.

Let me repeat: YOU WILL GET THE BALL THROUGH THE HOOP WITH THESE PARAMETERS

v_output = 12 m/s = 39 feet / s

height of muzzle = 2.5 feet

angle of muzzle = 30 degrees

horizontal distance from goal = 21 feet

See equations below:

Yes, this is no joke. Again, it's very clear that it is a solid solution that the veteran teams have already proven out. Let’s put our efforts into building a solid, accurate, robust shooter. There will be lots of accurate shooters this year. Let’s figure this one out.

- Emily

7 comments:

Wow. I guess we could be doing more in the "see what other people have already done for us" department. Let's get to work designing it, now that we know it will work.

whoa, their prototype is awesome.

to get the ball going at 12m/s and using the mini-bike cim motors, what size wheel diameter do you need?

the larger the faster right? my gut feeling is that we should probably have the biggest wheel possible, espeically if we have a guide. do we really need one though? baseball machines don't. neither does team 358's prototype.

i'm also kind of feeling the vertical wheel.

and believe me, i'm interested, but i have no clue how to go about solving it nor can the excel spreadsheet of motion load on my computer at home.

EMILY- i forget where you said you got the peanut-dispenser-accoridan-duct thing. we should get some of that for loading.

Yo kiddos.

They actually use a really small diameter wheel - 4". But that already gives them an output speed of 14 m/s.

Check out the blog thread on another blog about this shooter and how they built it:

http://www.chiefdelphi.com/forums/showthread.php?p=437158#post437158

(copy and paste the URL)

Ok that just had way too many typos. Let's try again.

So they're using a belt attached to the wheel and motor to get the wheel to spin, right? Wouldn't we want a chain, not a belt, because it wouldn't slip? Or is slipping okay when you have so much extra energy and you want to slow the ball down? But that wouldn't give you a repeatable shot...

Actually, to run it at those RPMs (rotations per minutes), chain is a little scary.

If you look inside a drill press for example, or inside a mill, you'll find that they are all belt driven. The traditional ones you actually need to pop the belt from one pulley to another to change the speed. Ask bud ;)

Post a Comment